Capability Analysis with JMP

This page demonstrates how process capability analysis is performed in JMP. For a broad overview of capability concepts and indexes, see process capability in Six Sigma.

What is Process Capability Analysis?

Process capability measures how well a process meets a specified outcome. It indicates whether a process conforms to specified requirements or specifications. Capability analysis helps assess the process's performance in meeting customer specifications and identify opportunities for improvement.

Process Capability Analysis Steps

- Determine the metric or parameter to measure and analyze.

- Collect the historical data for the parameter of interest.

- Prove the process is statistically stable (i.e., in control).

- Calculate the process capability indices.

- Monitor the process and ensure it remains in control over time. Update the process capability indices if needed.

Process Capability Indices

Process capability can be presented using various indices, depending on the process type and the analysis objective. Popular process capability indices are:

- Cp

- Pp

- Cpk

- Ppk

- Cpm

The Cp index is process capability. It assumes the process mean is centered between the specification limits and essentially is the ratio of the distance between the specification limits to six process standard deviations. Obviously, the higher this value, the better, because it means you can accommodate process variation within the spec limits more easily. Cp measures the process’s potential capability to meet the two-sided specifications. It does not account for the process average.

High Cp indicates a narrow process spread relative to the spread of the customer specifications. Cp is recommended when the process is centered between the specification limits. Cp is valid when both upper and lower specification limits are present. The higher Cp, the better, meaning the process spread is smaller relative to the specification spread.

Use JMP to Run a Process Capability Analysis

Data File: Capability Analysis” tab in “Sample Data.xlsx

Run Process Capability Analysis in JMP:

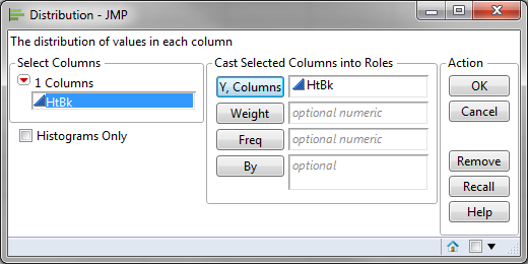

- Click Analyze -> Distribution

- Select “HtBk” as “Y, Columns”

- Click “OK”

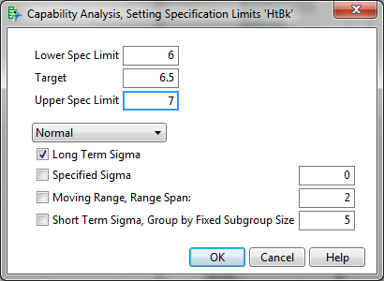

- Click on the red button next to “HtBk”

- Click “Capability Analysis”

- A window named “Capability Analysis, Setting Specification Limits” pops up

- Enter the 6.0 as the “Lower Spec Limit”, 6.5 as the “Target” and 7.0 as the “Upper Spec Limit”

- Click OK

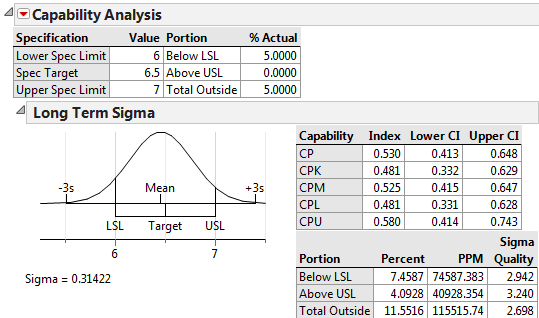

Model summary: With a CPK below 1.0, we conclude that this processis capability is poor. Anything below 1.0 should be considered not capable, and we should strive for CPK values above 1, preferably over 1.33.

About Lean Sigma Corporation

Lean Sigma Corporation is an independent Six Sigma certification authority responsible for the development, administration, and governance of professional Six Sigma credentials. The organization defines certification frameworks, examination standards, and credentialing systems used to evaluate and recognize Six Sigma competence across professional training environments.

Organizations and instructors delivering Six Sigma training under recognized standards participate in the Authorized Training Partner (ATP) Program.