What is Takt Time?

Takt time is a German word that means to keep in step, keep time, and stay in rhythm. The underlying rhythm is the customer demand. Takt time represents the available time for production or process completion divided by the customer demand or required output within that time frame. In simpler terms, it's the pace at which you need to produce or complete a task to match customer demand. Takt time helps organizations ensure that they are producing or delivering products or services in alignment with customer needs.

How Is Takt Time Calculated?

Before we discuss how takt time is calculated, you need to understand that Takt time is in fact, "calculated". It's not a measured outcome, it's simply an equation: Takt Time = Available Time / Demand, or, the pace at which production must flow to meet demand.

- Available Time refers to the total time available for production or work during a specific period, such as a day or shift.

- Demand is the quantity of products or services that customers require within the same time period.

For example, if a manufacturing plant operates for 480 minutes (8 hours) in a day and customer demand is 240 units per day, the takt time would be 2 minutes per unit (480 minutes / 240 units).

What Does Takt Time Mean?

Takt time serves as a critical benchmark for production or process efficiency. It acts as a heartbeat, setting the rhythm for operations. When the actual production time matches or aligns closely with takt time, it indicates that a process is operating efficiently and meeting customer demand without overproduction or underproduction. Deviations from takt time can highlight areas for improvement, such as bottlenecks or wasted time.

Why Should You Care About Takt Time?

Understanding and monitoring takt time is vital for several reasons:

- Customer Satisfaction: Takt time ensures that you are producing at the rate customers require, leading to better customer satisfaction.

- Efficiency: It helps identify inefficiencies in a process, enabling improvements to meet demand more effectively.

- Resource Allocation: Takt time guides resource allocation, including staffing and equipment, to match production needs.

- Waste Reduction: It aids in the elimination of overproduction, reducing waste and costs.

- Continuous Improvement: By tracking takt time, organizations can continually adjust and optimize their processes for better performance.

Online Takt Time Calculator

Enter Your Values in the "Inputs" Section.

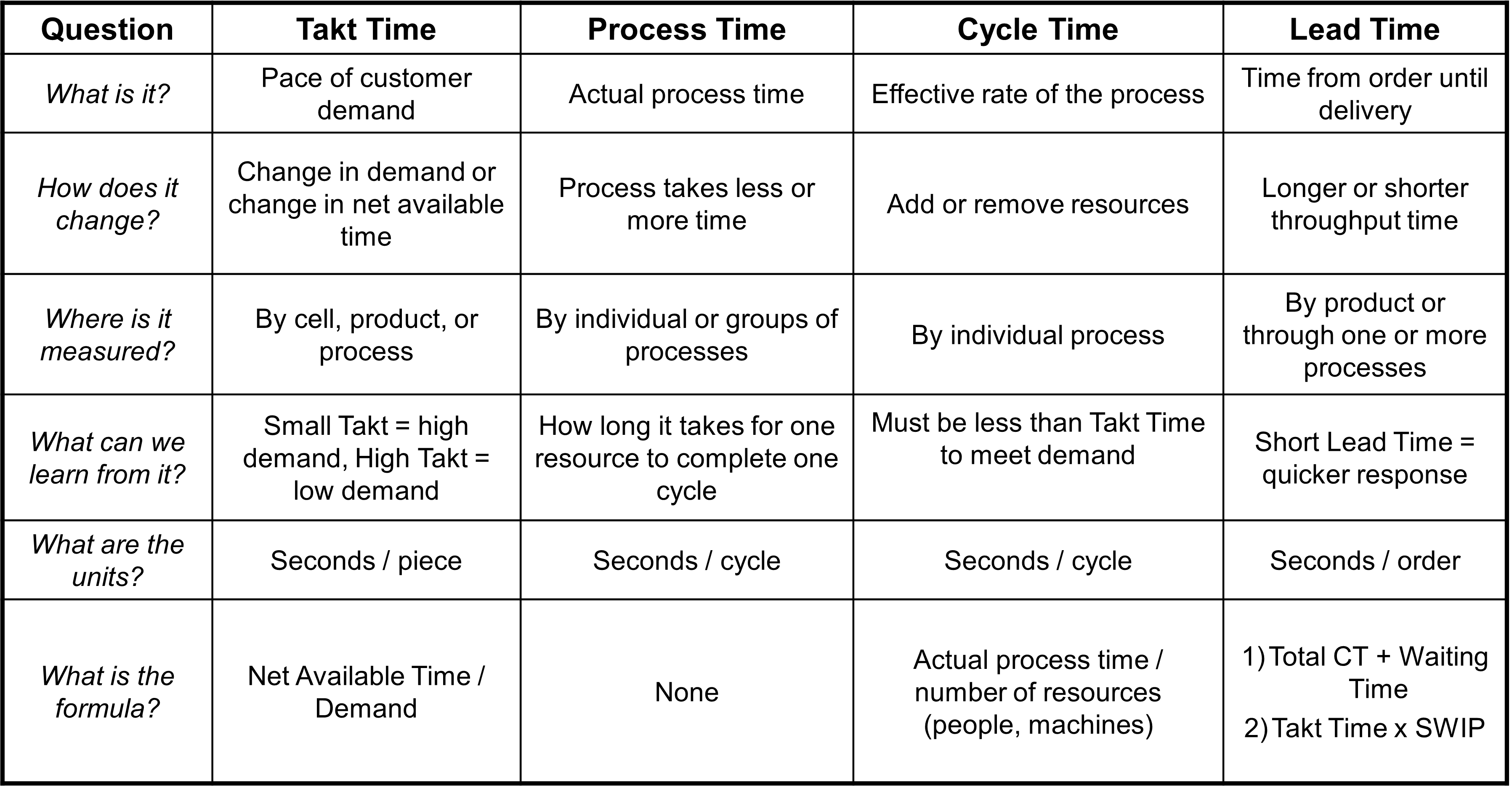

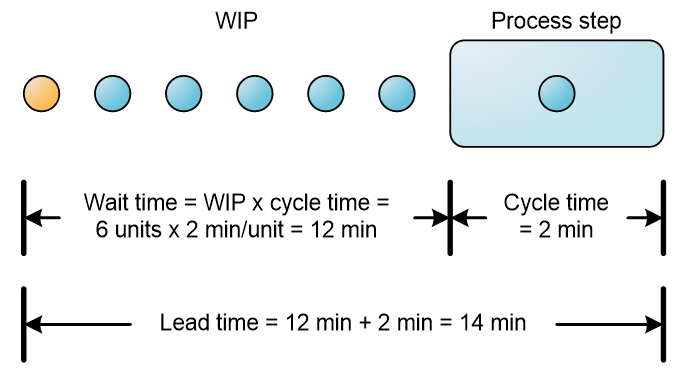

Understanding Cycle Time and Wait Time

Cycle time is the actual measured time it takes to complete a process step for one unit

- The measured time that elapses from the beginning of a process step or activity until it is completed, including walking time, manual operations, and machine operations. Where Takt time is based on customer demand, Cycle time is based on production time.

- Cycle time does not include the wait time of any WIP

Wait time is the time a unit waits from when it enters a queue until the downstream process begins work.

- Wait time is related to cycle time by Little’s law

- For example: If a process step has 6 units of WIP and cycle time is 2 min/unit

then; wait time = (6 units) x (2 min/unit) = 12 min - Wait time is also known as queue time.

- Little’s law is sometimes expressed as “wait time = WIP / completion rate”, where completion rate is defined in terms of units/min. Wait time can be measured or calculated from Little’s law, based on observations of WIP and cycle time.

Unit of Time is Important: The usual recommendation is to use seconds as the standard unit of time. However, if the process is slow then it is sometimes more useful to use minutes or even hours. In any case, it is important to maintain constant time units throughout.

For Reference:

1 h = 60 min = 3600 s

8 h = 480 min = 28,800 s

1 day = 24 h = 1440 min = 86,400 s

How Lead Time Relates to Cycle Time and Wait Time

Lead time is the sum of all the cycle times from all individual process steps within the value stream,

plus the wait times that exist between each process step.

In other words, the time needed for a unit to move from the start to the end of the value stream

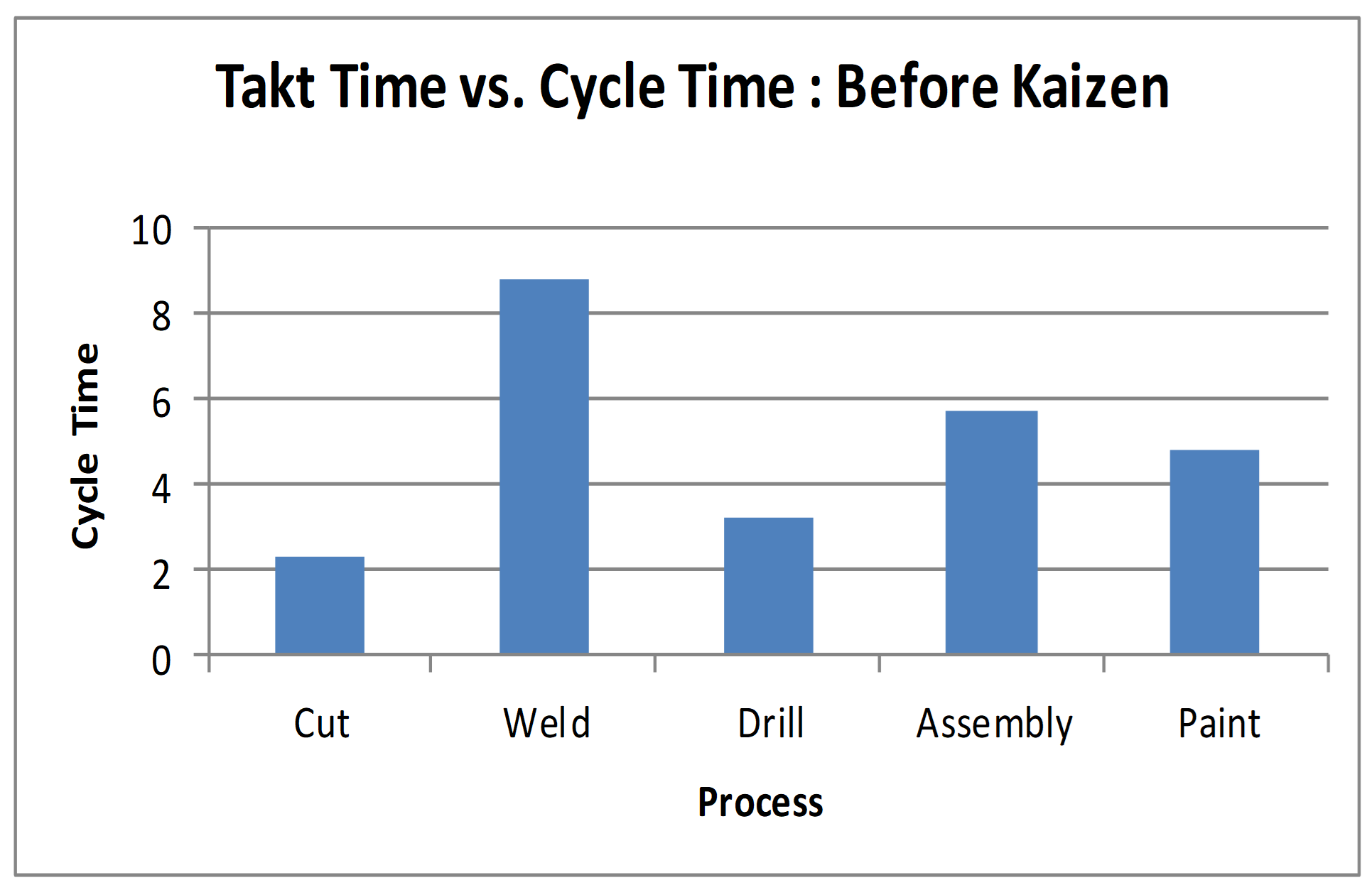

Understanding Takt Time as it Relates to Cycle Time

Takt Time is a calculated time, not a measured time.

Takt time = (available time per period) / (customer demand per period)

Cycle Time is the actual measured time it takes to complete a process step for one unit

If cycle time > takt time, bottlenecks can occur

If cycle time < takt time, idle time (waiting) can occur

Rule of thumb: cycle time should be 90 to 95% of takt time

Helpful Note: Takt time and cycle time can also be used to calculate ideal staffing levels:

Ideal staffing = (sum of manual cycle times) / (takt time)

For example, for a certain value stream with five process steps

with manual cycle times of 6 + 4 + 5 + 4 + 6 min respectively, and a takt time of 10 min.

Ideal staffing = (25 person-minutes) / (10 min) = 2.5 persons

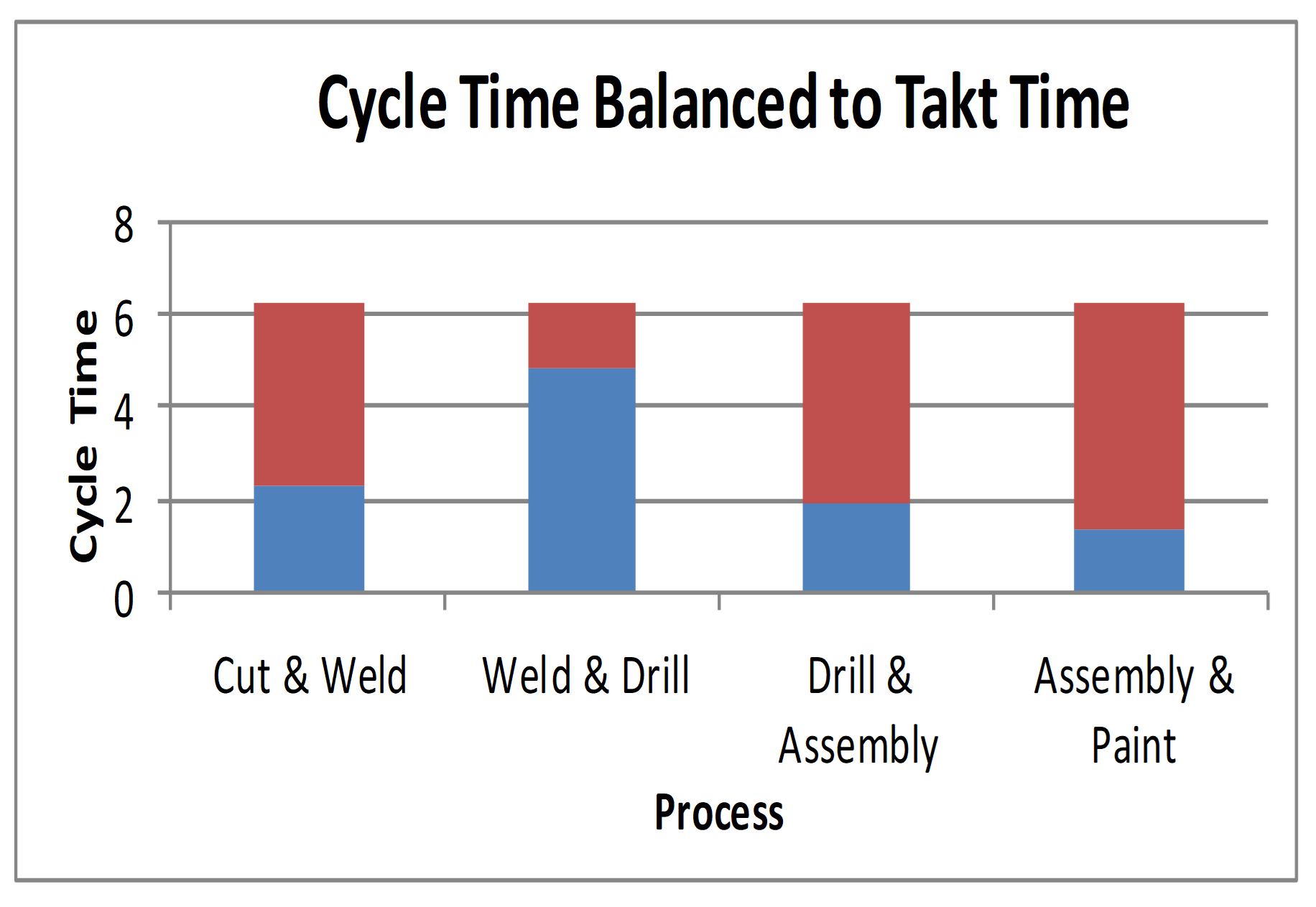

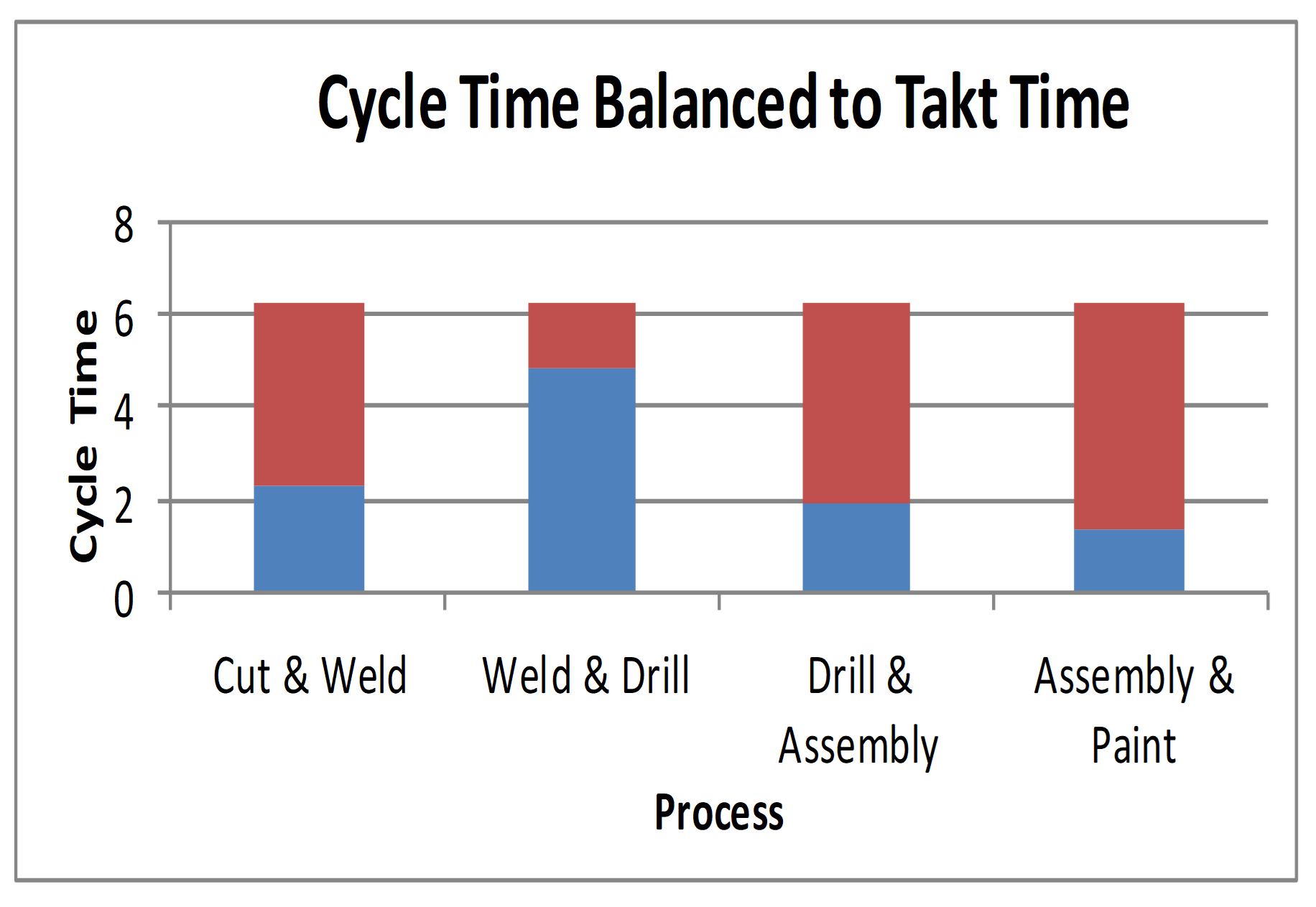

Balancing Cycle Time and Takt Time

Your Objective Should be to Attempt to Balance Cycle Time with Takt Time

Balancing all cycle times to Takt Time will result in a ‘just in time’ design.