Earn Up To 105 PDUs

Lean Six Sigma Certification

No Risk Money Back Guarantee | PDU's | Monthly Payment Plans | Lifetime Access

Choose Your Lean Six Sigma Certification Package for PDUs and Career Advancement.

50 PDUs

Lean Six Sigma

Yellow Belt Certification

Online Training & Certification

Lean Six Sigma Yellow Belt Certification - Course Details

| Course Title | Lessons | Quizzes |

Phase Tests |

Exam Attempts |

Exam Questions |

Pass Score |

Time Limit |

Pass Rate |

Sat. Rating | PDU |

Earned Designation |

Avg. Completion | Price |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lean Six Sigma Yellow Belt | 11 | 11 | 3 | 2 | 50 | 80% | 1Hr. | 97.9% | 96.4% | 50 | LSSYB | 27 Days | $595 |

Certification Requirements

- Complete all Lessons and Quizzes

- Pass all Phase Tests (unlimited attempts, passing score 80%)

- Pass the LSSYB Certification Exam (2 attempts, passing score 80%, 1hr. time limit)

- Complete the Required Course Feedback Form

Course Does Not Require a Project | Statistical Software is Not Required | Default Statistical References: Minitab. SigmaXL and JMP Versions are Available on Request | Curriculum Compatibility: Minitab v.22, SigmaXL v.10, JMP v.18. KEY: LSS = Lean Six Sigma | SS = Six Sigma | BB = Black Belt | GB = Green Belt | YB = Yellow Belt | PDU = Professional Development Units

Lean Six Sigma Yellow Belt Course Outline

-

Define Phase

Overview of Six Sigma

Six Sigma Fundamentals

Lean Six Sigma Projects

Lean Fundamentals

Define Phase Test

-

Measure Phase

Process Definition

Six Sigma Statistics

Measurement Systems

Process Capability

Measure Phase Test

-

Analyze PhasePatterns of Variation

Inferential Statistics

Hypothesis Testing

Hyp. Tests Normal

Hyp. Tests Non-Normal

Analyze Phase Test

-

Improve PhaseSimple Linear Regression

Multiple Regression

Design of Experiment

Full Factorial DOE

Fractional Factorial DOE

Improve Phase Test

-

Control Phase

Statistical Process Control

Six Sigma Control Plans

Lean Controls

Control Phase Test

LSSYB Certification Exam

-

DEFINE PHASE

-

Overview of Six Sigma

What is Six Sigma

Six Sigma History

Six Sigma Approach Y = f(x)

Six Sigma Methodology

Roles & Responsibilities -

Six Sigma Fundamentals

Defining a Process

VOC & CTQ's

QFD

Cost of Poor Quality

Pareto Analysis (80:20 rule) -

Lean Six Sigma Projects

Six Sigma Metrics

Rolled Throughput Yield

Business Case & Charter

Project Team Selection

Project Risk Management

Project Planning -

Lean Fundamentals

Lean and Six Sigma

History of Lean

Seven Deadly Muda

Five-S (5S)

Define Phase Test

-

MEASURE PHASE

-

Process Definition

Cause & Effect Diagram

Cause & Effect Matrix

Process Mapping

FMEA

Theory of Constraints -

Six Sigma Statistics

Basic Statistics

Descriptive Statistics

Distributions & Normality

Graphical Analysis -

MSA

Precision & Accuracy

Bias, Linearity & Stability

Gage R&R

Variable & Attribute MSA -

Process Capability

Capability Analysis

Concept of Stability

Attribute vs Discrete

Monitoring Techniques

Measure Phase Test

-

ANALYZE PHASE

-

Patterns of Variation

Multi-Vari Analysis

Classes of Distributions -

Inferential Statistics

Understanding Inference

Sampling Techniques

Sample Size

Central Limit Theorem -

Hypothesis Testing

Hypothesis Testing

Statistical Significance

Risk; Alpha & Beta

Types of Hypothesis Tests -

Hyp. Tests Normal

1-sample t-test

2-Sample t-test

Paired t-test

1-sample variance

One Way ANOVA -

Hyp. Tests Non-Normal

Mann-Whitney

Moods Median

Kruskal-Wallis / Friedman

1 Sample Sign & Wilcoxon

1 & 2 Sample Proportions

Chi-Squared

Test of Equal Variances

Analyze Phase Test

-

IMPROVE PHASE

-

Simple Linear Reg.

Correlation

X-Y Diagram

Regression Equations

Residuals Analysis -

Multiple Regression

Non-Linear Reg.

Multiple Linear Reg.

Confidence Intervals

Residuals Analysis

Box-Cox Transformation

Stepwise Regression

Logistic Regression -

Design of Experiment

Experiment Objectives

Experimental Methods

DOE Design Considerations -

Full Factorial DOE

2k Full Factorial Designs

Linear & Quadratic Models

Orthogonal Designs

Fit, Model & Center Points -

Fractional Factorial DOE

Fractional Designs

Confounding Effects

Experimental Resolution

Improve Phase Test

-

CONTROL PHASE

-

SPC

Data Collection for SPC

Individuals Charts

Xbar Charts

Proportions Charts

CumSum, EWMA Charts

Control Chart Anatomy

Subgroups & Sampling

Control Limits -

Lean Controls

Control Methods for 5S

Kanban

Poka-Yoke -

Six Sigma Control Plans

Cost Benefit Analysis

Control Plan Elements

Response Plan Elements

Control Phase Test -

LSSYB Certification Exam

85 PDUs

Lean Six Sigma

Green Belt Certification

Online Training & Certification

Lean Six Sigma Green Belt Certification - Course Details

| Course Title | Lessons | Quizzes |

Phase Tests |

Exam Attempts |

Exam Questions |

Pass Score |

Time Limit |

Pass Rate |

Sat. Rating | PDU |

Earned Designation |

Avg. Completion | Price |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lean Six Sigma Green Belt | 17 | 17 | 5 | 2 | 100 | 80% | 2Hrs. | 94.2% | 94.5% | 85 | LSSGB | 51 Days | $795 |

Certification Requirements

- Complete all Lessons and Quizzes

- Pass all Phase Tests (unlimited attempts, passing score 80%)

- Pass the LSSGB Certification Exam (2 attempts, passing score 80%, 2hr. time limit)

- Complete the Required Course Feedback Form

Course Does Not Require a Project | Statistical Software is Not Required | Default Statistical References: Minitab. SigmaXL and JMP Versions are Available on Request | Curriculum Compatibility: Minitab v.22, SigmaXL v.10, JMP v.18. KEY: LSS = Lean Six Sigma | SS = Six Sigma | BB = Black Belt | GB = Green Belt | YB = Yellow Belt | PDU = Professional Development Units

Lean Six Sigma Green Belt Course Outline

-

Define Phase

Overview of Six Sigma

Six Sigma Fundamentals

Lean Six Sigma Projects

Lean Fundamentals

Define Phase Test

-

Measure Phase

Process Definition

Six Sigma Statistics

Measurement Systems

Process Capability

Measure Phase Test

-

Analyze Phase

Patterns of Variation

Inferential Statistics

Hypothesis Testing

Hyp. Tests Normal

Hyp. Tests Non-Normal

Analyze Phase Test

-

Improve Phase

Simple Linear Regression

Multiple Regression

Design of Experiment

Full Factorial DOE

Fractional Factorial DOE

Improve Phase Test

-

Control Phase

Statistical Process Control

Six Sigma Control Plans

Lean Controls

Control Phase Test

LSSGB Certification Exam

-

DEFINE PHASE

-

Overview of Six Sigma

What is Six Sigma

Six Sigma History

Six Sigma Approach Y = f(x)

Six Sigma Methodology

Roles & Responsibilities -

Six Sigma Fundamentals

Defining a Process

VOC & CTQ's

QFD

Cost of Poor Quality

Pareto Analysis (80:20 rule) -

Lean Six Sigma Projects

Six Sigma Metrics

Rolled Throughput Yield

Business Case & Charter

Project Team Selection

Project Risk Management

Project Planning -

Lean Fundamentals

Lean and Six Sigma

History of Lean

Seven Deadly Muda

Five-S (5S)

Define Phase Test

-

MEASURE PHASE

-

Process Definition

Cause & Effect Diagram

Cause & Effect Matrix

Process Mapping

FMEA

Theory of Constraints -

Six Sigma Statistics

Basic Statistics

Descriptive Statistics

Distributions & Normality

Graphical Analysis -

MSA

Precision & Accuracy

Bias, Linearity & Stability

Gage R&R

Variable & Attribute MSA -

Process Capability

Capability Analysis

Concept of Stability

Attribute vs Discrete

Monitoring Techniques

Measure Phase Test

-

ANALYZE PHASE

-

Patterns of VariationMulti-Vari Analysis

Classes of Distributions -

Inferential Statistics

Understanding Inference

Sampling Techniques

Sample Size

Central Limit Theorem -

Hypothesis Testing

Hypothesis Testing

Statistical Significance

Risk; Alpha & Beta

Types of Hypothesis Tests -

Hyp. Tests Normal

1-sample t-test

2-Sample t-test

Paired t-test

1-sample variance

One Way ANOVA -

Hyp. Tests Non-Normal

Mann-Whitney

Moods Median

Kruskal-Wallis / Friedman

1 Sample Sign & Wilcoxon

1 & 2 Sample Proportions

Chi-Squared

Test of Equal Variances

Analyze Phase Test

-

IMPROVE PHASE

-

Simple Linear Reg.

Correlation

X-Y Diagram

Regression Equations

Residuals Analysis -

Multiple Regression

Non-Linear Reg.

Multiple Linear Reg.

Confidence Intervals

Residuals Analysis

Box-Cox Transformation

Stepwise Regression

Logistic Regression -

Design of ExperimentExperiment Objectives

Experimental Methods

DOE Design Considerations -

Full Factorial DOE2k Full Factorial Designs

Linear & Quadratic Models

Orthogonal Designs

Fit, Model & Center Points -

Fractional Factorial DOEFractional Designs

Confounding Effects

Experimental Resolution

Improve Phase Test

-

CONTROL PHASE

-

SPC

Data Collection for SPC

Individuals Charts

Xbar Charts

Proportions Charts

CumSum, EWMA Charts

Control Chart Anatomy

Subgroups & Sampling

Control Limits -

Lean Controls

Control Methods for 5S

Kanban

Poka-Yoke -

Six Sigma Control Plans

Cost Benefit Analysis

Control Plan Elements

Response Plan Elements

Control Phase Test -

LSSGB Certification Exam

105 PDUs

Lean Six Sigma

Black Belt Certification

Online Training & Certification

Lean Six Sigma Black Belt Certification - Course Details

| Course Title | Lessons | Quizzes |

Phase Tests |

Exam Attempts |

Exam Questions |

Pass Score |

Time Limit |

Pass Rate |

Sat. Rating | PDU |

Earned Designation |

Avg. Completion | Price |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lean Six Sigma Black Belt | 21 | 21 | 5 | 2 | 150 | 80% | 3Hrs. | 92.6% | 96.3% | 105 | LSSBB | 54 Days | $995 |

Certification Requirements

- Complete all Lessons and Quizzes

- Pass all Phase Tests (unlimited attempts, passing score 80%)

- Pass the LSSBB Certification Exam (2 attempts, passing score 80%, 3hr. time limit)

- Complete the Required Course Feedback Form

Course Does Not Require a Project | Statistical Software is Not Required | Default Statistical References: Minitab. SigmaXL and JMP Versions are Available on Request | Curriculum Compatibility: Minitab v.22, SigmaXL v.10, JMP v.18. KEY: LSS = Lean Six Sigma | SS = Six Sigma | BB = Black Belt | GB = Green Belt | YB = Yellow Belt | PDU = Professional Development Units

Lean Six Sigma Black Belt Course Outline

-

Define Phase

Overview of Six Sigma

Six Sigma Fundamentals

Lean Six Sigma Projects

Lean Fundamentals

Define Phase Test

-

Measure Phase

Process Definition

Six Sigma Statistics

Measurement Systems

Process Capability

Measure Phase Test

-

Analyze Phase

Patterns of Variation

Inferential Statistics

Hypothesis Testing

Hyp. Tests Normal

Hyp. Tests Non-Normal

Analyze Phase Test

-

Improve Phase

Simple Linear Regression

Multiple Regression

Design of Experiment

Full Factorial DOE

Fractional Factorial DOE

Improve Phase Test

-

Control Phase

Statistical Process Control

Six Sigma Control Plans

Lean Controls

Control Phase Test

LSSBB Certification Exam

-

DEFINE PHASE

-

Overview of Six Sigma

What is Six Sigma

Six Sigma History

Six Sigma Approach Y = f(x)

Six Sigma Methodology

Roles & Responsibilities -

Six Sigma Fundamentals

Defining a Process

VOC & CTQ's

QFD

Cost of Poor Quality

Pareto Analysis (80:20 rule) -

Lean Six Sigma Projects

Six Sigma Metrics

Rolled Throughput Yield

Business Case & Charter

Project Team Selection

Project Risk Management

Project Planning -

Lean Fundamentals

Lean and Six Sigma

History of Lean

Seven Deadly Muda

Five-S (5S)

Define Phase Test

-

MEASURE PHASE

-

Process Definition

Cause & Effect Diagram

Cause & Effect Matrix

Process Mapping

FMEA

Theory of Constraints -

Six Sigma Statistics

Basic Statistics

Descriptive Statistics

Distributions & Normality

Graphical Analysis -

MSA

Precision & Accuracy

Bias, Linearity & Stability

Gage R&R

Variable & Attribute MSA -

Process Capability

Capability Analysis

Concept of Stability

Attribute vs Discrete

Monitoring Techniques

Measure Phase Test

-

ANALYZE PHASE

-

Patterns of Variation

Multi-Vari Analysis

Classes of Distributions -

Inferential Statistics

Understanding Inference

Sampling Techniques

Sample Size

Central Limit Theorem -

Hypothesis Testing

Hypothesis Testing

Statistical Significance

Risk; Alpha & Beta

Types of Hypothesis Tests -

Hyp. Tests Normal

1-sample t-test

2-Sample t-test

Paired t-test

1-sample variance

One Way ANOVA -

Hyp. Tests Non-Normal

Mann-Whitney

Moods Median

Kruskal-Wallis / Friedman

1 Sample Sign & Wilcoxon

1 & 2 Sample Proportions

Chi-Squared

Test of Equal Variances

Analyze Phase Test

-

IMPROVE PHASE

-

Simple Linear Reg.

Correlation

X-Y Diagram

Regression Equations

Residuals Analysis -

Multiple Regression

Non-Linear Reg.

Multiple Linear Reg.

Confidence Intervals

Residuals Analysis

Box-Cox Transformation

Stepwise Regression

Logistic Regression -

Design of Experiment

Experiment Objectives

Experimental Methods

DOE Design Considerations -

Full Factorial DOE

2k Full Factorial Designs

Linear & Quadratic Models

Orthogonal Designs

Fit, Model & Center Points -

Fractional Factorial DOE

Fractional Designs

Confounding Effects

Experimental Resolution

Improve Phase Test

-

CONTROL PHASE

-

SPC

Data Collection for SPC

Individuals Charts

Xbar Charts

Proportions Charts

CumSum, EWMA Charts

Control Chart Anatomy

Subgroups & Sampling

Control Limits -

Lean Controls

Control Methods for 5S

Kanban

Poka-Yoke -

Six Sigma Control Plans

Cost Benefit Analysis

Control Plan Elements

Response Plan Elements

Control Phase Test -

LSSBB Certification Exam

All Certification Courses Include...

eBook

Included!

Training Slides

Included!

Quick Ref. Guide

Included!

Tools & Templates

Included!

Roadmaps

Included!

How-to Articles | Lifetime Access | Glossary

Lean Six Sigma Transformed My Career

Michael Parker

Founder - Master Black Belt

Like you, I was once an eager and determined professional who looked to make my mark in the corporate world. Twenty years ago, I met a Six Sigma Master Black Belt who insisted upon excellence and held me accountable. He provided me with guidance, expertise, and wisdom for the price of my eagerness and at his insistence, my patience.

His guidance led me down the rewarding path of Six Sigma, where I found something worthy of mastering. Six Sigma, as it turns out, was my true professional development, leading to my maturity, consistent promotions, career growth, and nearly doubling my salary upon certification.

If you have my kind of eagerness and enthusiasm, I have your kind of training and guidance. Together, we can write your story of success!

Customers and Clients

Choose Your Career Transformation Package

50 PDU

Lean Six Sigma Yellow Belt

Designed For: Executive-level decision-makers, managers, or subject matter experts (SMEs) who seek to understand Lean Six Sigma principles without the "Analyze or Improve" phases of the DMAIC methodology. Learn to understand!

Lean Six Sigma Yellow Belt Certification - Course Details

| Course Title | Lessons | Quizzes |

Phase Tests |

Exam Attempts |

Exam Questions |

Pass Score |

Time Limit |

Pass Rate |

Sat. Rating | PDU |

Earned Designation |

Avg. Completion | Price |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lean Six Sigma Yellow Belt | 11 | 11 | 3 | 2 | 50 | 80% | 1Hr. | 97.9% | 96.4% | 50 | LSSYB | 27 Days | $595 |

Certification Requirements

- Complete all Lessons and Quizzes

- Pass all Phase Tests (unlimited attempts, passing score 80%)

- Pass the LSSYB Certification Exam (2 attempts, passing score 80%, 1hr. time limit)

- Complete the Required Course Feedback Form

Course Does Not Require a Project | Statistical Software is Not Required | Default Statistical References: Minitab. SigmaXL and JMP Versions are Available on Request | Curriculum Compatibility: Minitab v.22, SigmaXL v.10, JMP v.18. KEY: LSS = Lean Six Sigma | SS = Six Sigma | BB = Black Belt | GB = Green Belt | YB = Yellow Belt | PDU = Professional Development Units

Lean Six Sigma Yellow Belt Course Outline

-

Define Phase

Overview of Six Sigma

Six Sigma Fundamentals

Lean Six Sigma Projects

Lean Fundamentals

Define Phase Test

-

Measure Phase

Process Definition

Six Sigma Statistics

Measurement Systems

Process Capability

Measure Phase Test

-

Analyze PhasePatterns of Variation

Inferential Statistics

Hypothesis Testing

Hyp. Tests Normal

Hyp. Tests Non-Normal

Analyze Phase Test

-

Improve PhaseSimple Linear Regression

Multiple Regression

Design of Experiment

Full Factorial DOE

Fractional Factorial DOE

Improve Phase Test

-

Control Phase

Statistical Process Control

Six Sigma Control Plans

Lean Controls

Control Phase Test

LSSYB Certification Exam

-

DEFINE PHASE

-

Overview of Six Sigma

What is Six Sigma

Six Sigma History

Six Sigma Approach Y = f(x)

Six Sigma Methodology

Roles & Responsibilities -

Six Sigma Fundamentals

Defining a Process

VOC & CTQ's

QFD

Cost of Poor Quality

Pareto Analysis (80:20 rule) -

Lean Six Sigma Projects

Six Sigma Metrics

Rolled Throughput Yield

Business Case & Charter

Project Team Selection

Project Risk Management

Project Planning -

Lean Fundamentals

Lean and Six Sigma

History of Lean

Seven Deadly Muda

Five-S (5S)

Define Phase Test

-

MEASURE PHASE

-

Process Definition

Cause & Effect Diagram

Cause & Effect Matrix

Process Mapping

FMEA

Theory of Constraints -

Six Sigma Statistics

Basic Statistics

Descriptive Statistics

Distributions & Normality

Graphical Analysis -

MSA

Precision & Accuracy

Bias, Linearity & Stability

Gage R&R

Variable & Attribute MSA -

Process Capability

Capability Analysis

Concept of Stability

Attribute vs Discrete

Monitoring Techniques

Measure Phase Test

-

ANALYZE PHASE

-

Patterns of Variation

Multi-Vari Analysis

Classes of Distributions -

Inferential Statistics

Understanding Inference

Sampling Techniques

Sample Size

Central Limit Theorem -

Hypothesis Testing

Hypothesis Testing

Statistical Significance

Risk; Alpha & Beta

Types of Hypothesis Tests -

Hyp. Tests Normal

1-sample t-test

2-Sample t-test

Paired t-test

1-sample variance

One Way ANOVA -

Hyp. Tests Non-Normal

Mann-Whitney

Moods Median

Kruskal-Wallis / Friedman

1 Sample Sign & Wilcoxon

1 & 2 Sample Proportions

Chi-Squared

Test of Equal Variances

Analyze Phase Test

-

IMPROVE PHASE

-

Simple Linear Reg.

Correlation

X-Y Diagram

Regression Equations

Residuals Analysis -

Multiple Regression

Non-Linear Reg.

Multiple Linear Reg.

Confidence Intervals

Residuals Analysis

Box-Cox Transformation

Stepwise Regression

Logistic Regression -

Design of Experiment

Experiment Objectives

Experimental Methods

DOE Design Considerations -

Full Factorial DOE

2k Full Factorial Designs

Linear & Quadratic Models

Orthogonal Designs

Fit, Model & Center Points -

Fractional Factorial DOE

Fractional Designs

Confounding Effects

Experimental Resolution

Improve Phase Test

-

CONTROL PHASE

-

SPC

Data Collection for SPC

Individuals Charts

Xbar Charts

Proportions Charts

CumSum, EWMA Charts

Control Chart Anatomy

Subgroups & Sampling

Control Limits -

Lean Controls

Control Methods for 5S

Kanban

Poka-Yoke -

Six Sigma Control Plans

Cost Benefit Analysis

Control Plan Elements

Response Plan Elements

Control Phase Test -

LSSYB Certification Exam

85 PDU

Lean Six Sigma Green Belt

Designed For: Individual contributors, project managers, analysts, or specialists, seeking to understand and apply Lean Six Sigma principles, utilizing the comprehensive DMAIC methodology to design improve business results.

Lean Six Sigma Green Belt Certification - Course Details

| Course Title | Lessons | Quizzes |

Phase Tests |

Exam Attempts |

Exam Questions |

Pass Score |

Time Limit |

Pass Rate |

Sat. Rating | PDU |

Earned Designation |

Avg. Completion | Price |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lean Six Sigma Green Belt | 17 | 17 | 5 | 2 | 100 | 80% | 2Hrs. | 94.2% | 94.5% | 85 | LSSGB | 51 Days | $795 |

Certification Requirements

- Complete all Lessons and Quizzes

- Pass all Phase Tests (unlimited attempts, passing score 80%)

- Pass the LSSGB Certification Exam (2 attempts, passing score 80%, 2hr. time limit)

- Complete the Required Course Feedback Form

Course Does Not Require a Project | Statistical Software is Not Required | Default Statistical References: Minitab. SigmaXL and JMP Versions are Available on Request | Curriculum Compatibility: Minitab v.22, SigmaXL v.10, JMP v.18. KEY: LSS = Lean Six Sigma | SS = Six Sigma | BB = Black Belt | GB = Green Belt | YB = Yellow Belt | PDU = Professional Development Units

Lean Six Sigma Green Belt Course Outline

-

Define Phase

Overview of Six Sigma

Six Sigma Fundamentals

Lean Six Sigma Projects

Lean Fundamentals

Define Phase Test

-

Measure Phase

Process Definition

Six Sigma Statistics

Measurement Systems

Process Capability

Measure Phase Test

-

Analyze Phase

Patterns of Variation

Inferential Statistics

Hypothesis Testing

Hyp. Tests Normal

Hyp. Tests Non-Normal

Analyze Phase Test

-

Improve Phase

Simple Linear Regression

Multiple Regression

Design of Experiment

Full Factorial DOE

Fractional Factorial DOE

Improve Phase Test

-

Control Phase

Statistical Process Control

Six Sigma Control Plans

Lean Controls

Control Phase Test

LSSGB Certification Exam

-

DEFINE PHASE

-

Overview of Six Sigma

What is Six Sigma

Six Sigma History

Six Sigma Approach Y = f(x)

Six Sigma Methodology

Roles & Responsibilities -

Six Sigma Fundamentals

Defining a Process

VOC & CTQ's

QFD

Cost of Poor Quality

Pareto Analysis (80:20 rule) -

Lean Six Sigma Projects

Six Sigma Metrics

Rolled Throughput Yield

Business Case & Charter

Project Team Selection

Project Risk Management

Project Planning -

Lean Fundamentals

Lean and Six Sigma

History of Lean

Seven Deadly Muda

Five-S (5S)

Define Phase Test

-

MEASURE PHASE

-

Process Definition

Cause & Effect Diagram

Cause & Effect Matrix

Process Mapping

FMEA

Theory of Constraints -

Six Sigma Statistics

Basic Statistics

Descriptive Statistics

Distributions & Normality

Graphical Analysis -

MSA

Precision & Accuracy

Bias, Linearity & Stability

Gage R&R

Variable & Attribute MSA -

Process Capability

Capability Analysis

Concept of Stability

Attribute vs Discrete

Monitoring Techniques

Measure Phase Test

-

ANALYZE PHASE

-

Patterns of VariationMulti-Vari Analysis

Classes of Distributions -

Inferential Statistics

Understanding Inference

Sampling Techniques

Sample Size

Central Limit Theorem -

Hypothesis Testing

Hypothesis Testing

Statistical Significance

Risk; Alpha & Beta

Types of Hypothesis Tests -

Hyp. Tests Normal

1-sample t-test

2-Sample t-test

Paired t-test

1-sample variance

One Way ANOVA -

Hyp. Tests Non-Normal

Mann-Whitney

Moods Median

Kruskal-Wallis / Friedman

1 Sample Sign & Wilcoxon

1 & 2 Sample Proportions

Chi-Squared

Test of Equal Variances

Analyze Phase Test

-

IMPROVE PHASE

-

Simple Linear Reg.

Correlation

X-Y Diagram

Regression Equations

Residuals Analysis -

Multiple Regression

Non-Linear Reg.

Multiple Linear Reg.

Confidence Intervals

Residuals Analysis

Box-Cox Transformation

Stepwise Regression

Logistic Regression -

Design of ExperimentExperiment Objectives

Experimental Methods

DOE Design Considerations -

Full Factorial DOE2k Full Factorial Designs

Linear & Quadratic Models

Orthogonal Designs

Fit, Model & Center Points -

Fractional Factorial DOEFractional Designs

Confounding Effects

Experimental Resolution

Improve Phase Test

-

CONTROL PHASE

-

SPC

Data Collection for SPC

Individuals Charts

Xbar Charts

Proportions Charts

CumSum, EWMA Charts

Control Chart Anatomy

Subgroups & Sampling

Control Limits -

Lean Controls

Control Methods for 5S

Kanban

Poka-Yoke -

Six Sigma Control Plans

Cost Benefit Analysis

Control Plan Elements

Response Plan Elements

Control Phase Test -

LSSGB Certification Exam

105 PDU

Lean Six Sigma Black Belt

Designed For: High performers who wish to be leaders and seek advanced problem-solving skills with the ability to train others in Lean Six Sigma concepts and principles. Black Belts are facilitators, mentors, and instructors.

Lean Six Sigma Black Belt Certification - Course Details

| Course Title | Lessons | Quizzes |

Phase Tests |

Exam Attempts |

Exam Questions |

Pass Score |

Time Limit |

Pass Rate |

Sat. Rating | PDU |

Earned Designation |

Avg. Completion | Price |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lean Six Sigma Black Belt | 21 | 21 | 5 | 2 | 150 | 80% | 3Hrs. | 92.6% | 96.3% | 105 | LSSBB | 54 Days | $995 |

Certification Requirements

- Complete all Lessons and Quizzes

- Pass all Phase Tests (unlimited attempts, passing score 80%)

- Pass the LSSBB Certification Exam (2 attempts, passing score 80%, 3hr. time limit)

- Complete the Required Course Feedback Form

Course Does Not Require a Project | Statistical Software is Not Required | Default Statistical References: Minitab. SigmaXL and JMP Versions are Available on Request | Curriculum Compatibility: Minitab v.22, SigmaXL v.10, JMP v.18. KEY: LSS = Lean Six Sigma | SS = Six Sigma | BB = Black Belt | GB = Green Belt | YB = Yellow Belt | PDU = Professional Development Units

Lean Six Sigma Black Belt Course Outline

-

Define Phase

Overview of Six Sigma

Six Sigma Fundamentals

Lean Six Sigma Projects

Lean Fundamentals

Define Phase Test

-

Measure Phase

Process Definition

Six Sigma Statistics

Measurement Systems

Process Capability

Measure Phase Test

-

Analyze Phase

Patterns of Variation

Inferential Statistics

Hypothesis Testing

Hyp. Tests Normal

Hyp. Tests Non-Normal

Analyze Phase Test

-

Improve Phase

Simple Linear Regression

Multiple Regression

Design of Experiment

Full Factorial DOE

Fractional Factorial DOE

Improve Phase Test

-

Control Phase

Statistical Process Control

Six Sigma Control Plans

Lean Controls

Control Phase Test

LSSBB Certification Exam

-

DEFINE PHASE

-

Overview of Six Sigma

What is Six Sigma

Six Sigma History

Six Sigma Approach Y = f(x)

Six Sigma Methodology

Roles & Responsibilities -

Six Sigma Fundamentals

Defining a Process

VOC & CTQ's

QFD

Cost of Poor Quality

Pareto Analysis (80:20 rule) -

Lean Six Sigma Projects

Six Sigma Metrics

Rolled Throughput Yield

Business Case & Charter

Project Team Selection

Project Risk Management

Project Planning -

Lean Fundamentals

Lean and Six Sigma

History of Lean

Seven Deadly Muda

Five-S (5S)

Define Phase Test

-

MEASURE PHASE

-

Process Definition

Cause & Effect Diagram

Cause & Effect Matrix

Process Mapping

FMEA

Theory of Constraints -

Six Sigma Statistics

Basic Statistics

Descriptive Statistics

Distributions & Normality

Graphical Analysis -

MSA

Precision & Accuracy

Bias, Linearity & Stability

Gage R&R

Variable & Attribute MSA -

Process Capability

Capability Analysis

Concept of Stability

Attribute vs Discrete

Monitoring Techniques

Measure Phase Test

-

ANALYZE PHASE

-

Patterns of Variation

Multi-Vari Analysis

Classes of Distributions -

Inferential Statistics

Understanding Inference

Sampling Techniques

Sample Size

Central Limit Theorem -

Hypothesis Testing

Hypothesis Testing

Statistical Significance

Risk; Alpha & Beta

Types of Hypothesis Tests -

Hyp. Tests Normal

1-sample t-test

2-Sample t-test

Paired t-test

1-sample variance

One Way ANOVA -

Hyp. Tests Non-Normal

Mann-Whitney

Moods Median

Kruskal-Wallis / Friedman

1 Sample Sign & Wilcoxon

1 & 2 Sample Proportions

Chi-Squared

Test of Equal Variances

Analyze Phase Test

-

IMPROVE PHASE

-

Simple Linear Reg.

Correlation

X-Y Diagram

Regression Equations

Residuals Analysis -

Multiple Regression

Non-Linear Reg.

Multiple Linear Reg.

Confidence Intervals

Residuals Analysis

Box-Cox Transformation

Stepwise Regression

Logistic Regression -

Design of Experiment

Experiment Objectives

Experimental Methods

DOE Design Considerations -

Full Factorial DOE

2k Full Factorial Designs

Linear & Quadratic Models

Orthogonal Designs

Fit, Model & Center Points -

Fractional Factorial DOE

Fractional Designs

Confounding Effects

Experimental Resolution

Improve Phase Test

-

CONTROL PHASE

-

SPC

Data Collection for SPC

Individuals Charts

Xbar Charts

Proportions Charts

CumSum, EWMA Charts

Control Chart Anatomy

Subgroups & Sampling

Control Limits -

Lean Controls

Control Methods for 5S

Kanban

Poka-Yoke -

Six Sigma Control Plans

Cost Benefit Analysis

Control Plan Elements

Response Plan Elements

Control Phase Test -

LSSBB Certification Exam

When You're Lean Six Sigma Certified!

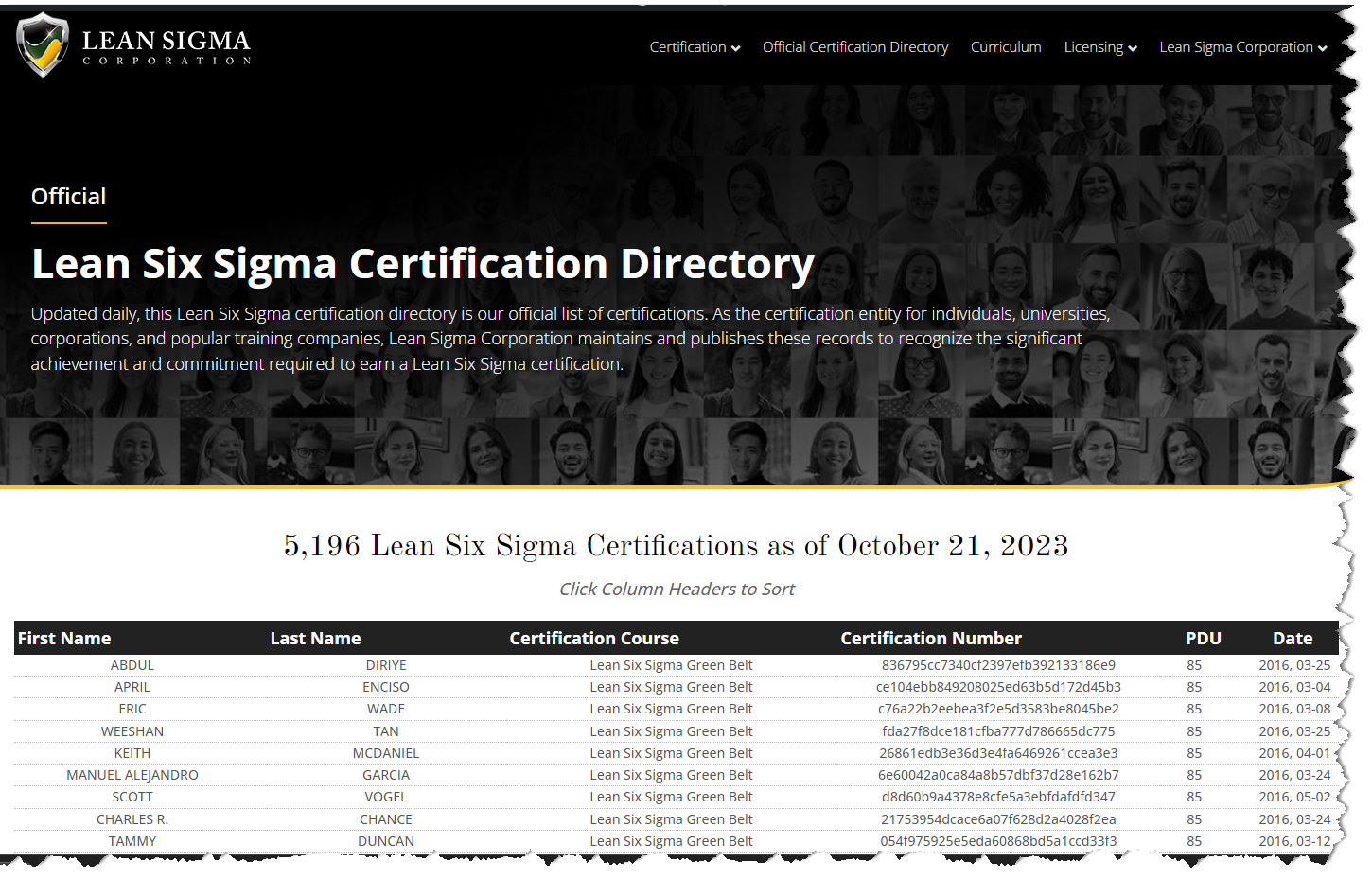

Certification Directory Listing

Entry into our Official Certification Directory showcases your achievements to the world.

Custom Digital Certificate

A symbol of your professional expertise and achievement.

Satisfied and Already Certified!

"I took Six Sigma many years ago while at Hewlett Packard, and this training has given me the needed skills to look for project management roles to grow my career."

Anthony Anderson

"Fantastic course organized in a very efficient and easy-to-learn manner. The reference materials provided were also excellent, and knowing that I will have access to them in the future is a huge bonus. I would highly recommend this course."

Michael Weigele

Frequently Asked Questions

All of our courses provide Professional Development Units referred to as PDUs. One PDU is equivalent to 1 contact hour of professional development. Our course offerings and their PDU's are list below:

Two

All of our courses and Exams allow for two certification exam attempts.

The passing score is 80%

- Yellow Belt - Understand Six Sigma

- For Decision-Makers and Contributors Seeking to Understand the Principals of Six Sigma without the Analysis or Improvement Phases of DMAIC. Methodology

- Green Belt - Apply Six Sigma

- For Specialists Seeking to Understand and Apply Six Sigma principles utilizing the Comprehensive D.M.A.I.C. Methodology to Design Better Processes and Improve Results

- Black Belt - Lead with Six Sigma

- For Process Leaders Seeking Advanced problem-solving skills and the Ability to Apply Six Sigma principles and DMAIC Methodology to Solve Complex Challenges and Drive Efficiency and Excellence

- Black Belts also teach, coach, and mentor Green Belts

The top three differences between Six Sigma and Lean Six Sigma are:

Content - Lessons added to Six Sigma to get Lean Six Sigma

- Lean Fundamentals

- Lean and Six Sigma

- History of Lean

- Seven Deadly Muda

- Five-S (5S)

- Lean Controls

- Control Methods for 5S

- Kanban

- Poke-Yoke

Earned Designation

- Lean Six Sigma Black Belt: LSSBB

- Lean Six Sigma Green Belt: LSSGB

- Lean Six Sigma Yellow Belt: LSSYB

- Six Sigma Black Belt: SSBB

- Six Sigma Green Belt: SSGB

- Six Sigma Yellow Belt: SSYB

Price

- Lean Six Sigma Black Belt $995

- Lean Six Sigma Green Belt $795

- Lean Six Sigma Yellow Belt $595

- Six Sigma Black Belt $795

- Six Sigma Green Belt $595

- Six Sigma Yellow Belt $395

No, there are no prerequisites for Yellow Belt, Green Belt, or Black Belt certification. There is, however, a prerequisite for Master Black Belt certification, which is Black Belt certification.

No, there are no educational or industry prerequisites for Yellow Belt, Green Belt, or Black Belt.

Yes. We offer stand-alone Six Sigma and Lean Six Sigma certification exams.

No. Our content and courses do reference statistical software, but the courses can be completed successfully without software.

The default statistical software referenced in our courses is Minitab. Courses referencing SigmaXL and JMP are available on request.

All software providers offer a free trial. You can (encouraged) download a free trial and follow closely along in our training to gain valuable new knowledge and analytical skills.

All of our courses provide two certification exam attempts.

If you do not pass on the second attempt, you may purchase a test reset, giving you two more attempts. Test resets can be found on your account page: https://leansigmacorporation.com/account

No, statistical software is not necessary for our certification exams.