10 Reasons Operational Excellence Deployments Fail

What most people don’t realize is that a majority of operational excellence deployments are destined to fail before they even start. In fact, in our experience, we have determined that there are 10 reasons operational excellence deployments fail.

Occasionally, deployments die quickly (being canceled 12 to 18 months after starting), however, most programs languish for years in a near-death state. These programs train a few people and work a few projects but they never deliver the benefits that they could.

In our practice, we have developed a deployment method that is proven to help clients avoid the 10 reasons operational excellence deployments fail and instead, deliver significant improvements year after year. To better understand how our approach is different you must first understand why most operational excellence deployments fail.

10 Reasons Operational Excellence Deployments Fail:

- Not defining the correct deployment purpose

- Lack of Executive support

- Lack of the correct philosophical assumptions to drive decision-making

- Not aligning improvement projects to what is most important to the company

- Failure to provide the necessary resources to complete projects

- Trying to fix everything…. Right now!

- Trying to design, implement, and manage the deployment by yourself

- Focus on training everyone, not on executing projects

- Managing your projects by project stage completion dates

- Creating an overly bureaucratic system

Each failure point is a result of a decision by leadership. By analyzing each failure point on the basis of “what type of behavior will this decision drive” and “what assumptions could have driven the decision to be made” you will be better prepared to avoid making these mistakes yourself. The analysis of each failure mode will be defined in depth in later articles.

The ten failure modes can be grouped into six classifications; philosophical assumptions, deployment purpose, focus and actions, organizational structure, and the methods of managing and measuring performance. Each of the failure modes serves to weaken your deployment in unique ways and by different amounts.

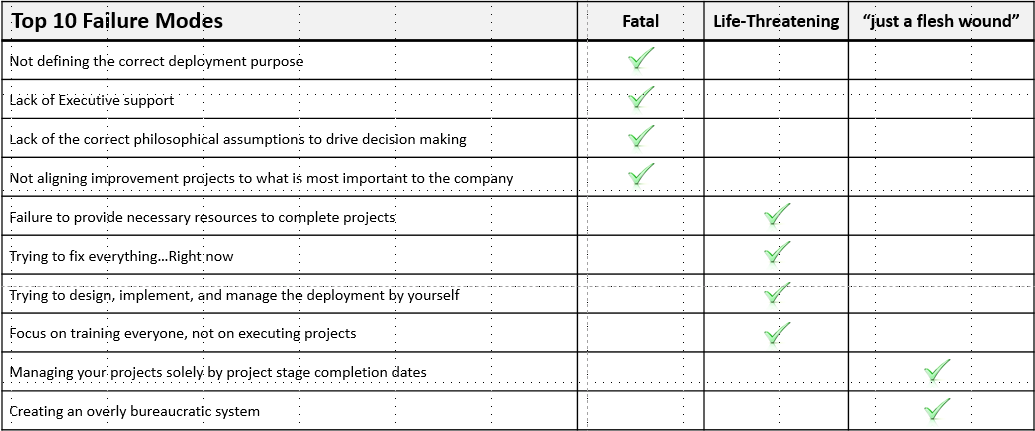

Some failure modes are fatal, some are life-threatening, and some would be described by Monty Python as “just a flesh wound”.

While deploying your program you may miss 8 failure modes, but it doesn’t matter, the 2 mistakes you do make could kill your program. This is a risk you can’t take.

Money and enthusiasm will not save your deployment, in order to be successful, you must prepare for and eliminate all 10 reasons operational excellence deployments fail.

Additionally, this is not something that can be done solely while the deployment is in motion, this process must start before you deploy. We have learned that the key to avoiding these ten failure modes is in how the deployment is designed and managed.

About Lean Sigma Corporation

Lean Sigma Corporation is an independent Six Sigma certification authority responsible for the development, administration, and governance of professional Six Sigma credentials. The organization defines certification frameworks, examination standards, and credentialing systems used to evaluate and recognize Six Sigma competence across professional training environments.

Organizations and instructors delivering Six Sigma training under recognized standards participate in the Authorized Training Partner (ATP) Program.