Full Factorial DOE with Minitab

What is a Full Factorial DOE?

In a full factorial experiment, all of the possible combinations of factors and levels are created and tested. For example, for two-level design (i.e.each factor has two levels) with k factors, there are 2k possible scenarios or treatments.

- Two factors, each with two levels, we have 22 = 4 treatments

- Three factors, each with two levels, we have 23 = 8 treatments

- k factors, each with two levels, we have 2k treatments

2k Full Factorial DOE

Full factorial DOE is used to discover the cause-and-effect relationship between the response and both individual factors and the interaction of factors. Generate an equation to describe the relationship between Y and the important Xs

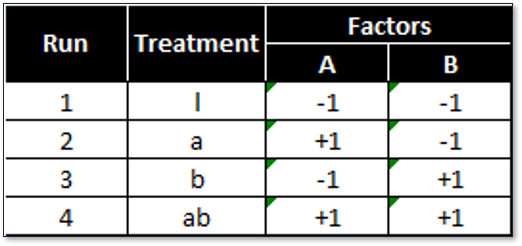

Two-Level Two-Factor Full Factorial

Below is a design pattern of a two-level two-factor full factorial experiment.

2 (level) raised to 2 (factors) = 4 treatment combinations.

2 (level) raised to 2 (factors) = 4 treatment combinations.

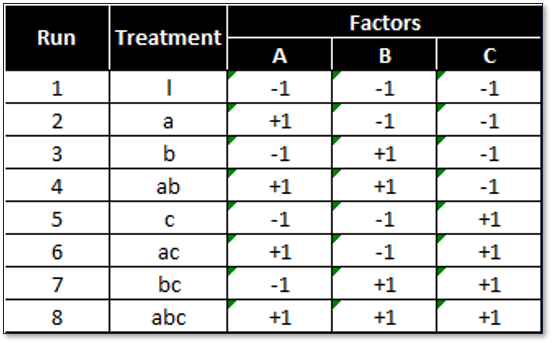

Two-Level Three-Factor Full Factorial

Below is a design pattern of a two-level three-factor full factorial experiment.

2 (levels) raised to 3 (factors) = 8 treatment combinations.

2 (levels) raised to 3 (factors) = 8 treatment combinations.

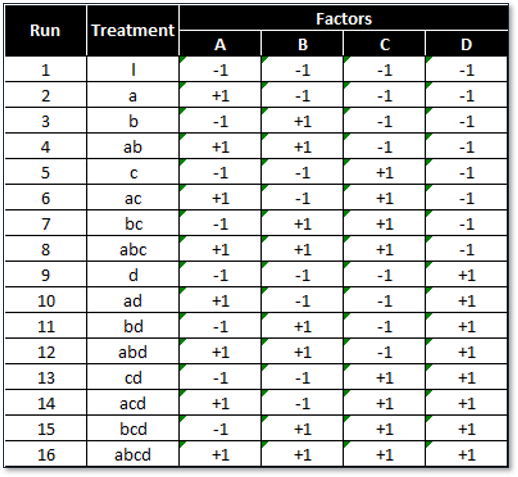

Two-Level Four-Factor Full Factorial

Below is a design pattern of a two-level four-factor full factorial experiment

2 (levels) raised to 4 (factors) = 16 treatment combinations

2 (levels) raised to 4 (factors) = 16 treatment combinations

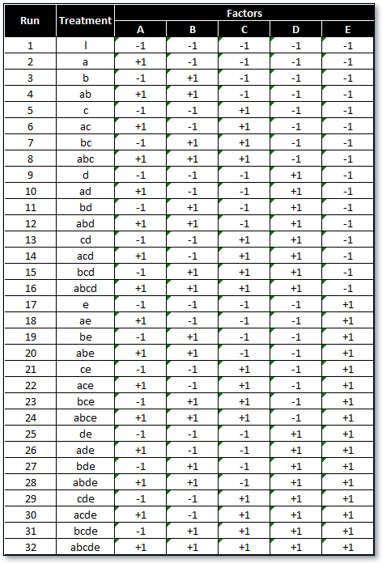

Two-Level Five-Factor Full Factorial

Below is a design pattern of a two-level five-factor full factorial experiment

2 (levels) raised to 5 (factors) = 32 treatment combinations

2 (levels) raised to 5 (factors) = 32 treatment combinations

Order to Run Experiments

The four design patterns shown earlier are listed in the standard order. Standard order is used to design the combinations/treatments before experiments start. When actually running the experiments, randomizing the standard order is recommended to minimize the noise.

Replication in Experiments

Each treatment can be tested multiple times in an experiment in order to increase the degrees of freedom and improve the capability of analysis. We call this method replication.

Replicates are the number of repetitions of running an individual treatment, which increase the power of the experimental responses. The order to run the treatments in an experiment should be randomized to minimize the noise.

Advantages of replication include: helping to better identify the true sources of variation, helping estimate the true impacts of the factors on the response, and overall improving the reliability and validity of the experimental results.

22 Full Factorial DOE

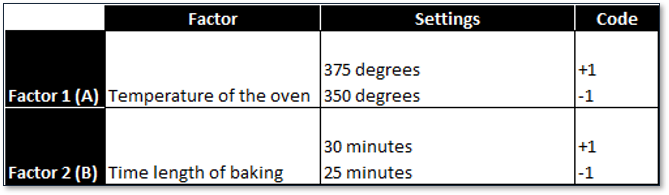

Case study: We are running a 22 full factorial DOE to discover the cause-and-effect relationship between the cake tastiness and two factors: temperature of the oven and time length of baking. Each factor has two levels and there are four treatments in total. We decide to run each treatment twice so that we have enough degrees of freedom to measure the impact of two factors and the interaction between two factors. Therefore, there are eight observations in response eventually.

We decide to run each treatment twice so that we have enough degrees of freedom to measure the impact of two factors and the interaction between two factors. Therefore, there are eight observations in response eventually.

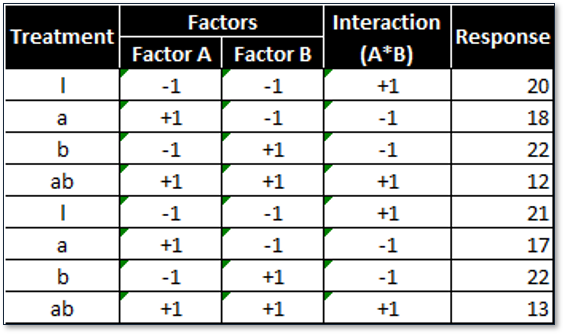

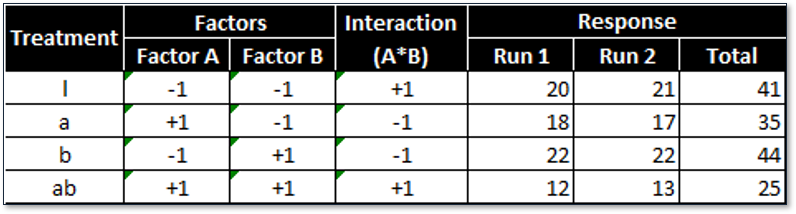

The objective is to understand the main effects and the interactions of these factors on the response variable. After running the four treatments twice in a random order, we obtain the following results

There are two factors and two levels, so there would be 2^2 = 4 treatment combinations. With replicates, each treatment combination is repeated once; therefore, there are in total 8 runs in this experiment. The experiment results are consolidated into the following table

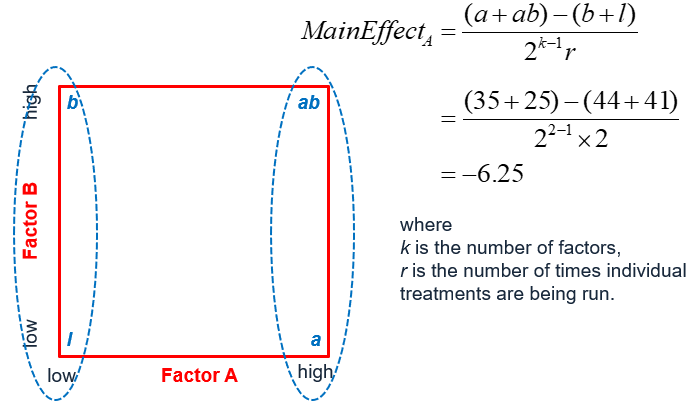

The main effect of factor A is computed by averaging the difference between combinations where A was at its high settings and where A was at its low settings.

The main effect of factor A is computed by averaging the difference between combinations where A was at its high settings and where A was at its low settings.

Main effect of factor A (temperature of the oven):

Using the formula provided, the main effect of increasing the temperature of the oven is to decrease the tastiness of the cake by −6.25.

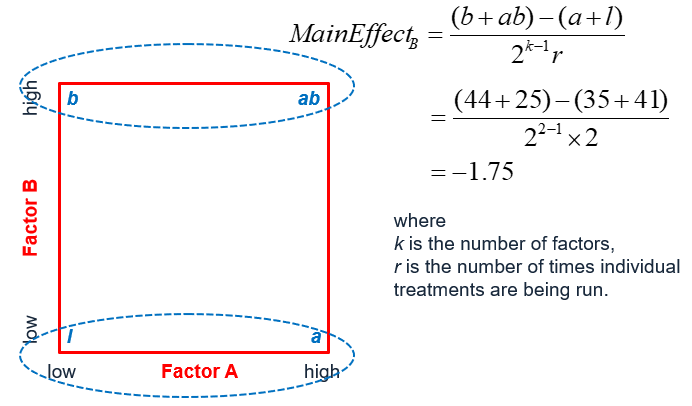

The main effect of factor B, similar to A, is computed by averaging the difference between combinations where B was at its high settings and where B was at its low settings.

The main effect of factor B (time length of baking):

Using the formula provided, the main effect of increasing the baking time is to decrease the tastiness of the cake by −1.75

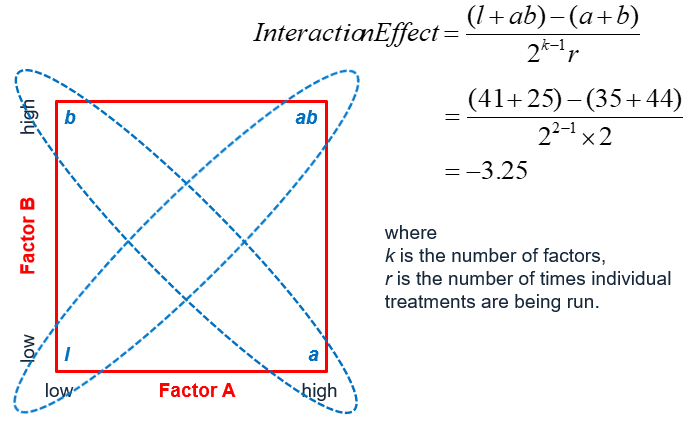

The interaction effect is computed by averaging the difference between combinations where A and B were at opposite settings (low and high).

Interaction (i.e. A*B) effect:

Using the formula provided, the interaction effect of the temperature and time variables on tastiness was −3.25.

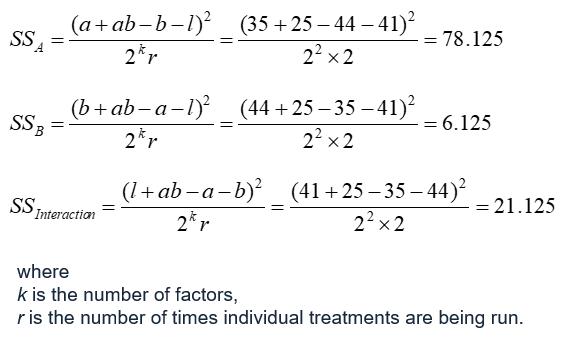

Sum of squares of factors and interaction

The sum of squares tells us the relative strength of each main effect and interaction. A has the strongest effect as indicated by the high SS value.

Use Minitab to Run a 2k Full Factorial DOE

Step 1: Initiate the experiment design

- Click Stat → DOE → Factorial → Create Factorial Design.

- A new window named “Create Factorial Design” pops up.

- Select the button of “General full factorial design.”

- Select “2” as the “Number of factors.”

- Click the “Design” button and a new window named “Create Factorial Design – Designs” pops up.

- Enter the factor name “Temperature” for factor A.

- Enter the factor name “Time Length” for factor B.

- Enter the number of levels “2” for both factor A and B.

- Enter “2” as the “Number of replicates.

- Click “OK” button in the window “Create Factorial Design – Designs.”

Step 2: Enter the factors and make the design

- Click on the “Factors” button in the window “Create Factorial Design”

- A new window named “Create Factorial Design – Factors” pops up.

- Select “Text” as the “Type” of both factor A and B.

- Enter “Low” and “High” as the two levels for both factor A and B.

- Click “OK” in the window “Create Factorial Design – Factors.”

- Click “OK” in the window “Create Factorial Design.”

- The design table is created in the data table.

Step 3: Run your experiment and record the response for each run in a new column named Tastiness within the table created by Minitab. Because we are simulating a DOE we have provided the data for you in the Sample Data.xlsx file. Use this data to populate your table with your experiment results

Step 4: Analyze the experiment results

- Click Stat → DOE → Factorial → Analyze Factorial Design.

- A new window named “Analyze Factorial Design” appears.

- Select “Tastiness” in the list box of “Responses.”

- Click on the “Storage” button and a new window named “Analyze Factorial Design – Storage” pops up.

- Check the boxes “Fits” and “Residuals” in the window “Analyze Factorial Design – Storage.”

- Click “OK” in the window “Analyze Factorial Design – Storage.”

- Click “OK” in the window “Analyze Factorial Design.”

- The DOE analysis results appear in the session window.

These are the results.

Since the p-values of all the independent variables in the model are smaller than the alpha level (0.05), both factors and their interactions have statistically significant impact on the response.

High R2 value shows around 98% of the variation in the response can be explained by the model (very good results).

The fitted response and the residuals of the DOE model are stored in the last two columns of the data table.

Model summary: These are the software outputs for expected/predicted results, as well as the residuals for each combination.

Model summary: These are the software outputs for expected/predicted results, as well as the residuals for each combination.

About Lean Sigma Corporation

Lean Sigma Corporation is an independent Six Sigma certification authority responsible for the development, administration, and governance of professional Six Sigma credentials. The organization defines certification frameworks, examination standards, and credentialing systems used to evaluate and recognize Six Sigma competence across professional training environments.

Organizations and instructors delivering Six Sigma training under recognized standards participate in the Authorized Training Partner (ATP) Program.