Overview of Six Sigma

What is Six Sigma | Methodology | Approach | History | Roles & Responsibilities | Quiz

What is Six Sigma

σ

In Statistics, the Greek Letter sigma (σ)

Refers to “Standard Deviation,” a Measure of Variation.

In Business, Variation (σ) Exists in All Processes

Variation Occurs Naturally and/or by Special Cause. It Doesn't Matter if You're Creating Widgets in Production, or Serving Patients in Healthcare.

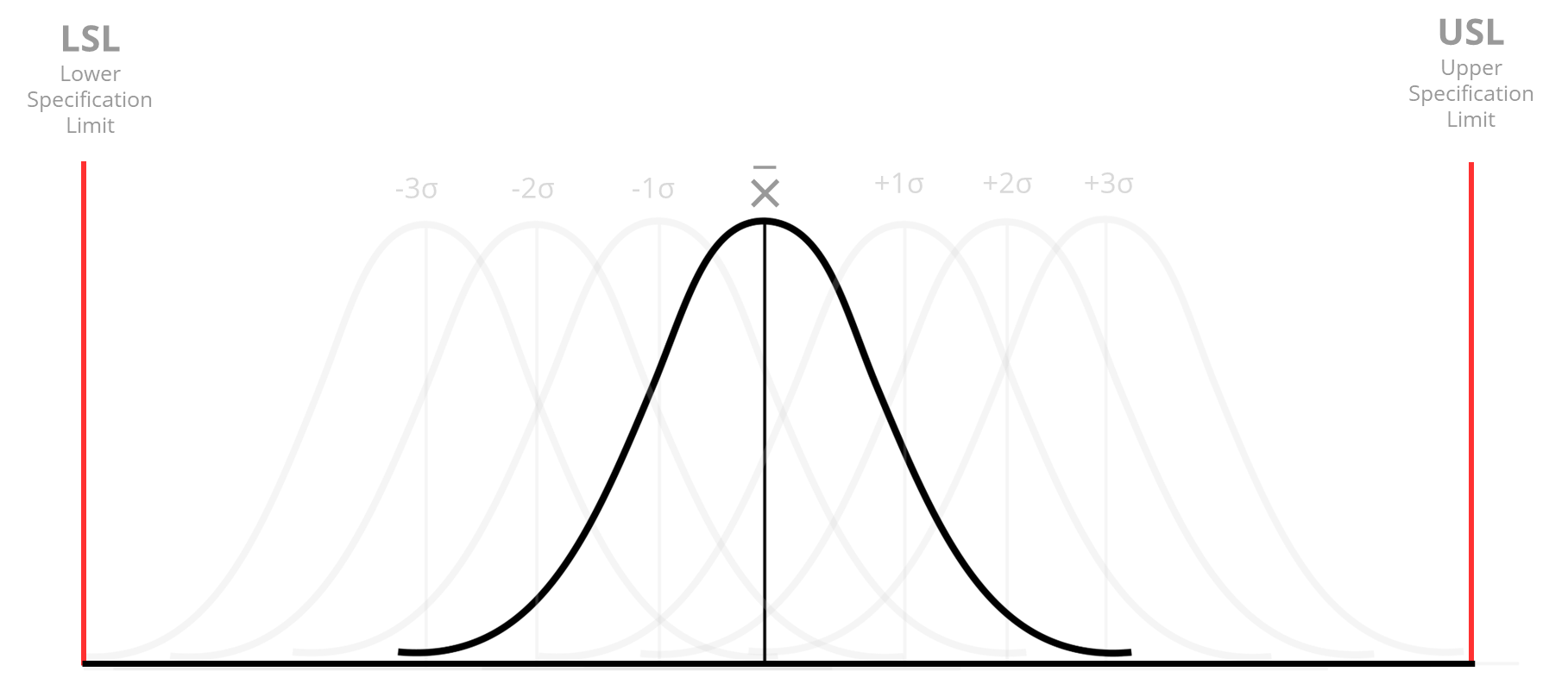

A Six Sigma Process

A Six Sigma Process Has Six (6) σ Between its Mean and the Nearest Specification Limit. There is Ample Room for Natural Variation. This Process Only Yields 3.4 Defects per Million Opportunities.

Specification Limits Can Be Set by Customers or Businesses

LSL = Lower Specification Limit | USL = Upper Specification Limit

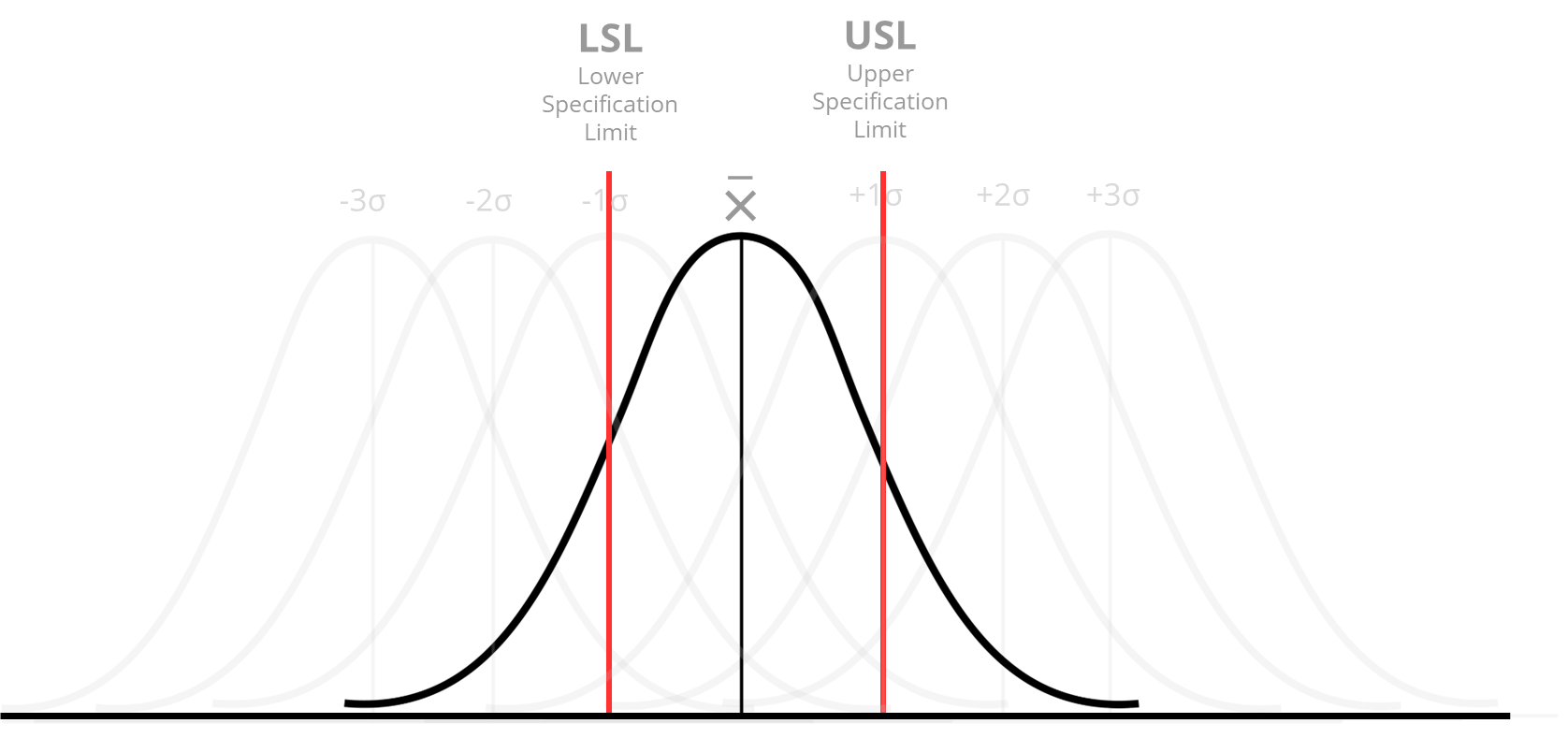

A One Sigma Process

A One Sigma Process Has Only One (1) σ Between its Mean and the Nearest Specification Limit. There is No Room for Natural Variation. This Process Yields Nearly 70% Defects.

Specification Limits Can Be Set by Customers or Businesses

LSL = Lower Specification Limit | USL = Upper Specification Limit

Sigma (σ) is the Measure

Six (6) is the Goal

.

.

.

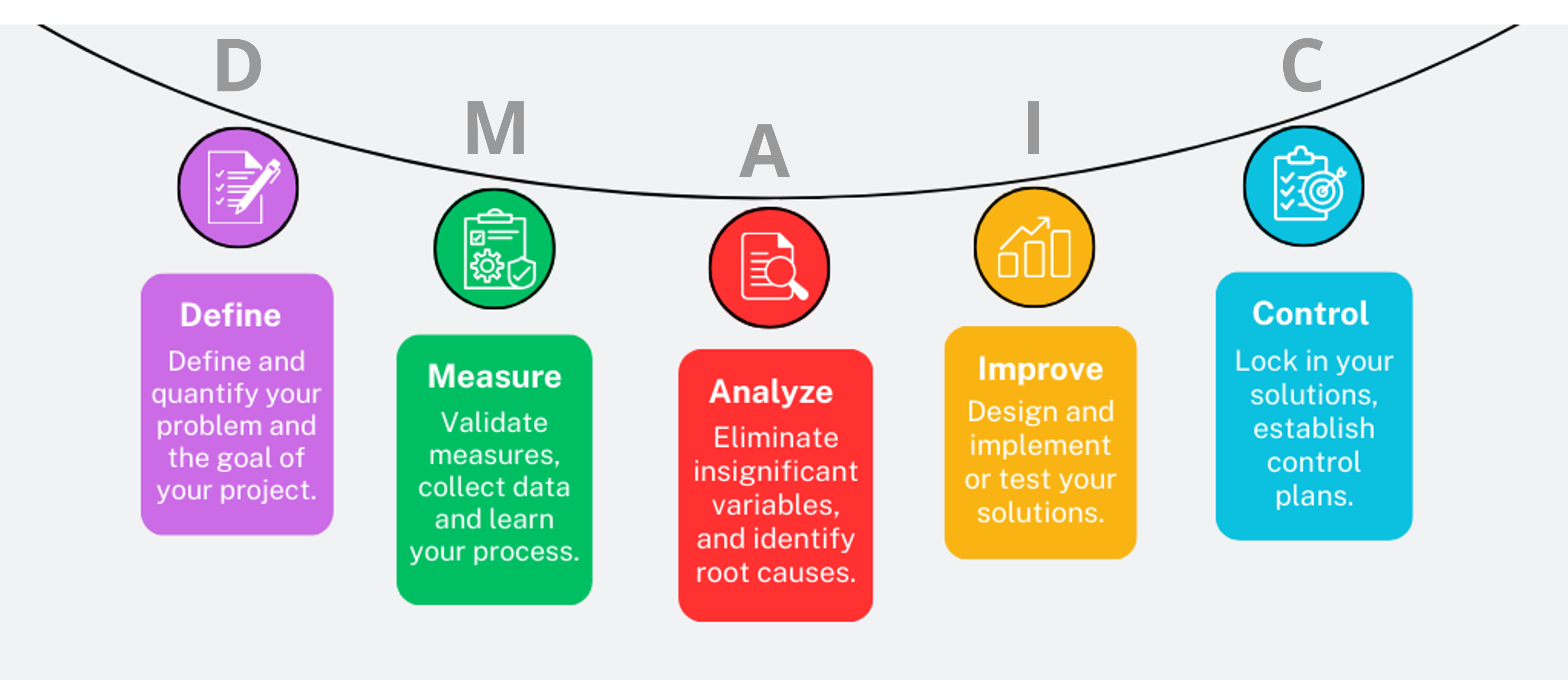

D.M.A.I.C is the Method..

Sigma is the Measure | Six Sigma is the Goal | D.M.A.I.C. is the Method Used to Achieve the Goal

D.M.A.I.C. is a Project Management Methodology.

D.M.A.I.C. is Used When We Don't Know the Answer.

Otherwise, Use a Traditional Project Management Method (Waterfall, Agile)

Six Sigma Methodology

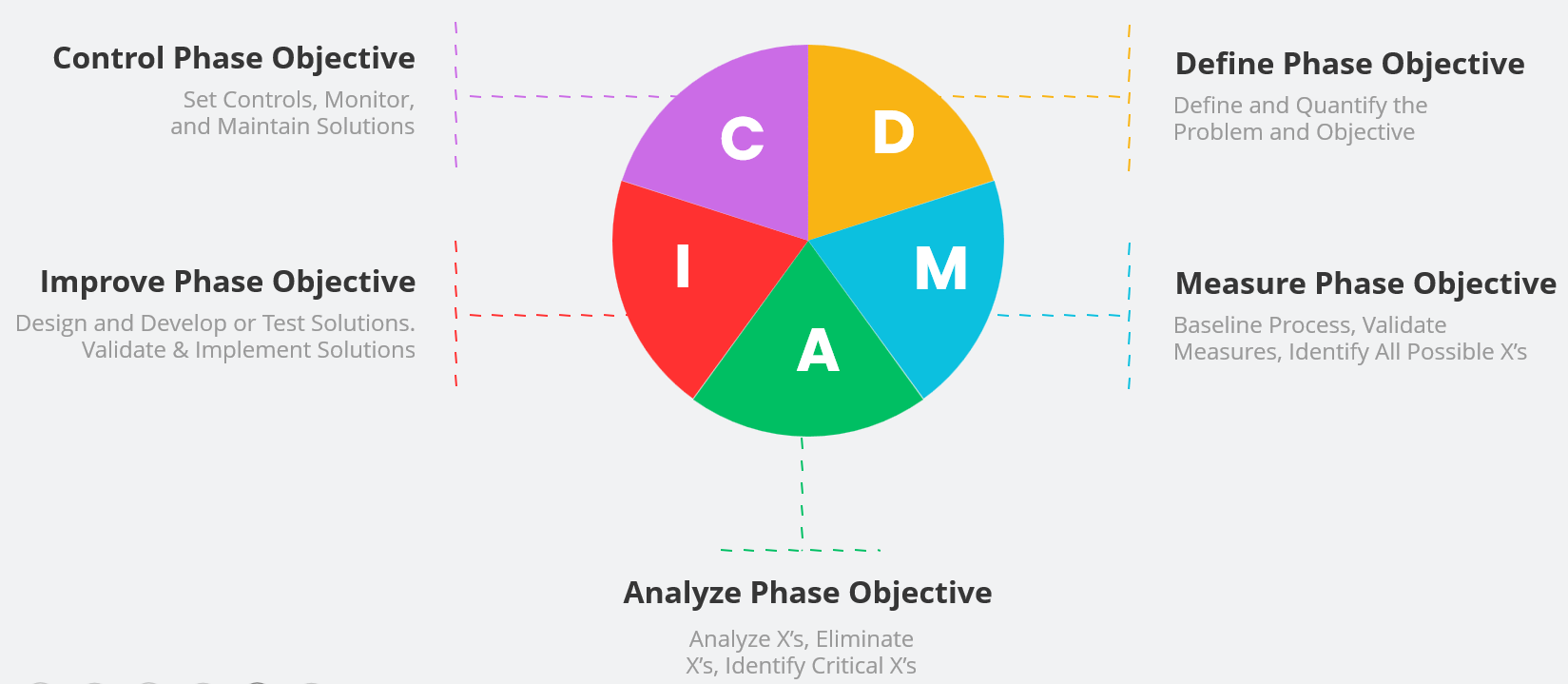

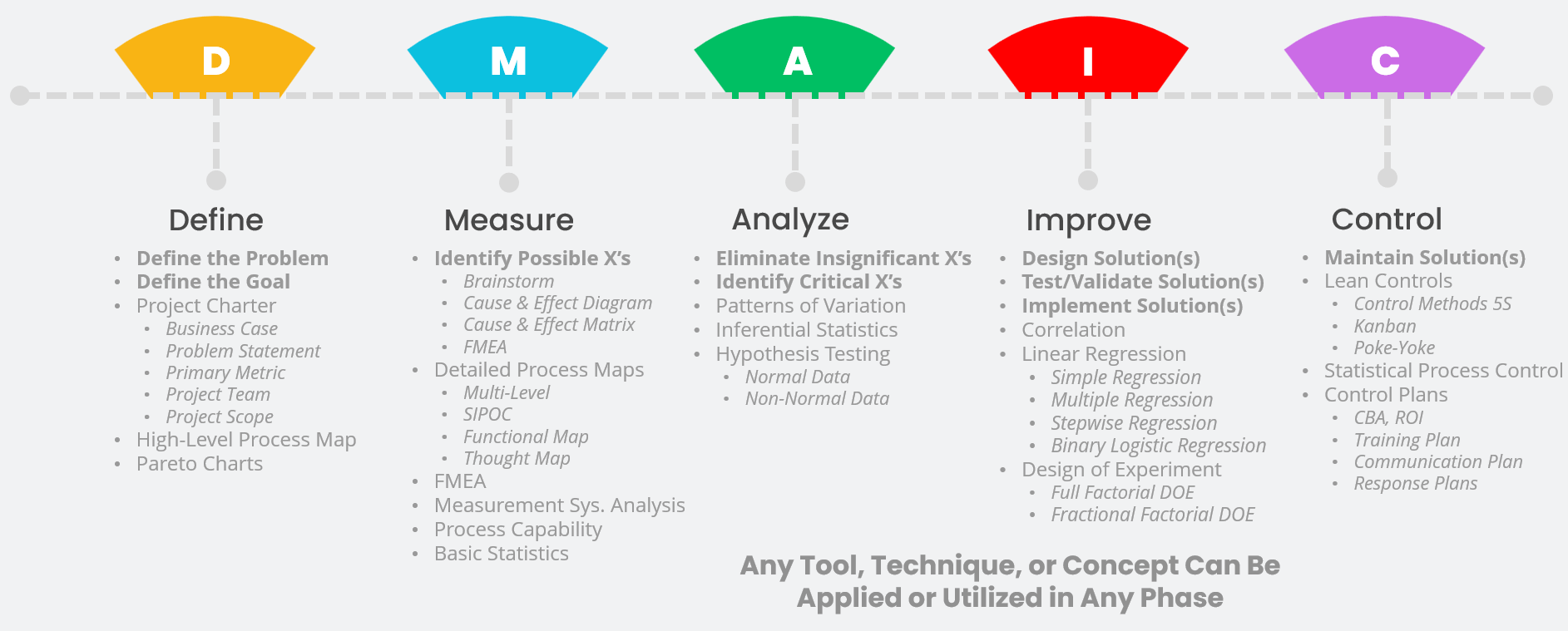

Six Sigma follows a methodology that is conceptually rooted in the principles of a five-phase project. Each phase has a specific purpose and specific tools and techniques that aid in achieving the phase objectives.

D.M.A.I.C. is a Process Taught from Define Through Control

However

D.M.A.I.C. is NOT Strictly Linear

Y=f(x) is a transfer function.

It is a Mathematical Expression of the Relationship Between the Inputs and Outputs of a System.

Y = f(x) is the Relational Transfer Function That is Used by All Six Sigma Practitioners.

It is critical that you understand and embrace this concept.

As a Six Sigma Practitioner, Your Job is to Use The DMAIC Methodology,

Weed Through All the Noise, and Identify the Critical X's

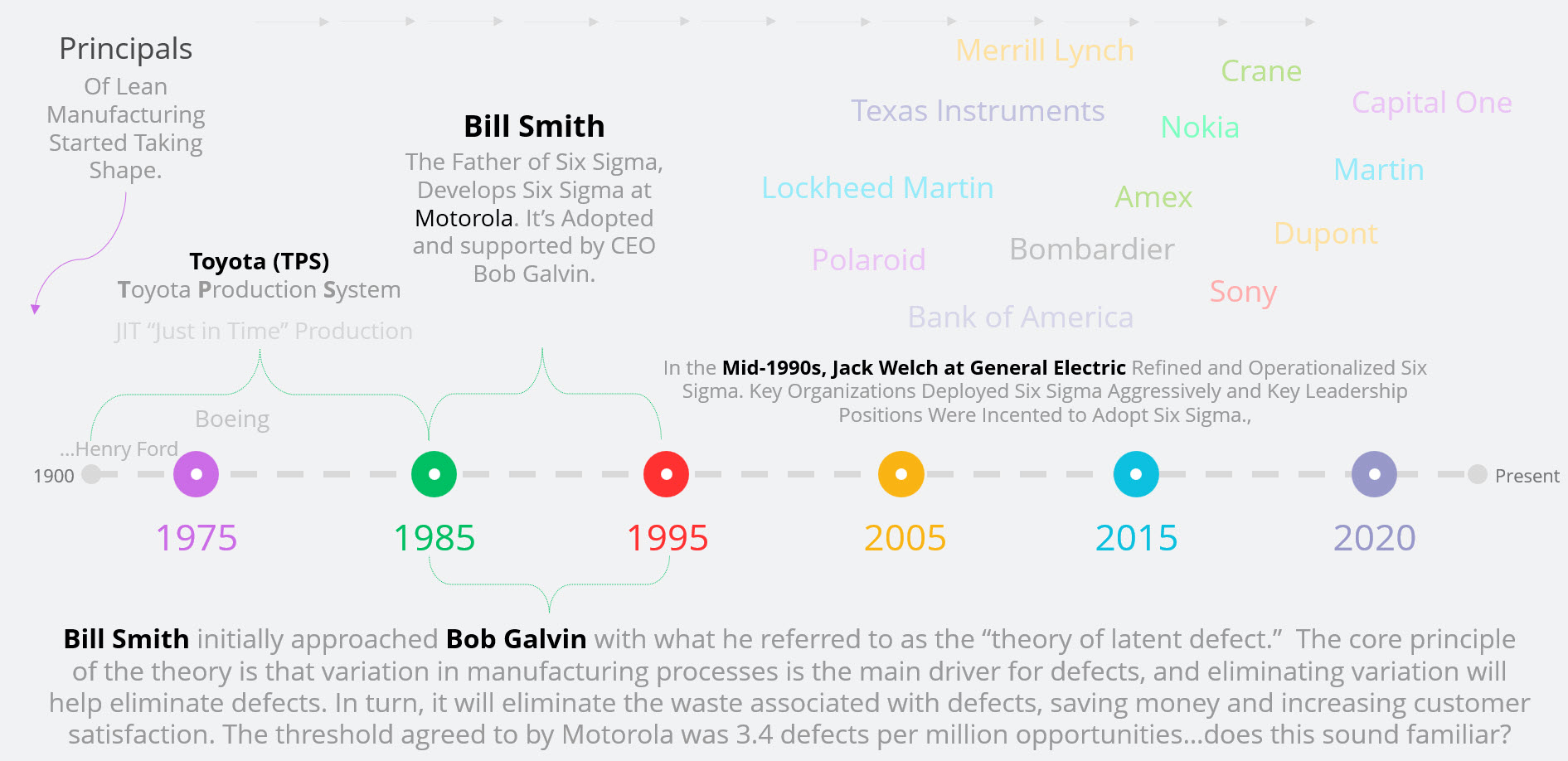

Lean Six Sigma History

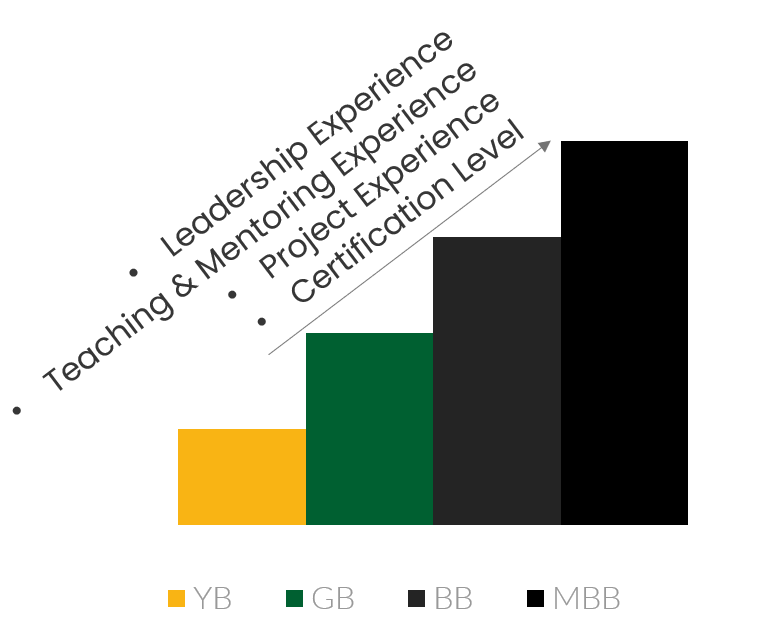

DESIGNATIONS

SS = Six Sigma

LSS = Lean Six Sigma

YB = Yellow Belt

GB = Green Belt

BB = Black Belt

MBB = Master Black Belt

NOTES

MBBs and BBs Facilitate Training and Mentor Others.

Master Black Belts Advise Champions and Sponsors.

Champions and Sponsors Should be Yellow Belt Trained.