History of Six Sigma

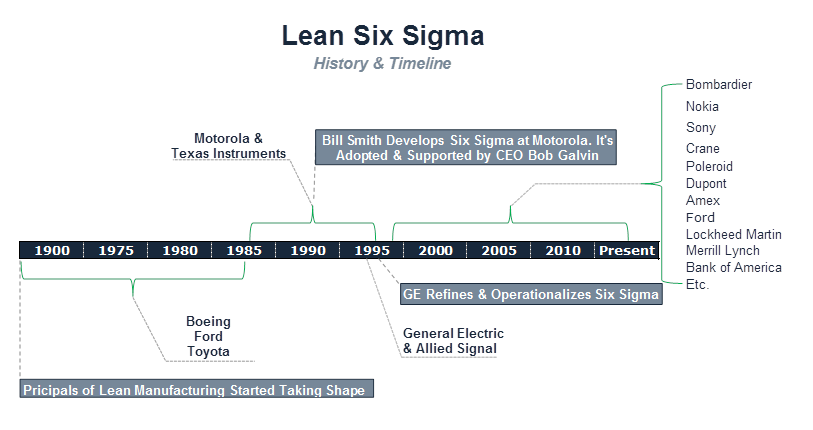

The history of Six Sigma finds its roots and terminology being first used by Bill Smith at Motorola in the late 1980s, as a quality management methodology. As the "Father of Six Sigma”, Bill forged the path for Six Sigma through Motorola's CEO Bob Galvin who strongly supported Bill's passion and efforts.

Starting from the late 1980s, Motorola extensively applied Six Sigma as a process management discipline throughout its company, leveraging Motorola University. In 1988, Motorola was recognized with the prestigious Malcolm Baldrige National Quality Award for its achievement in quality improvement.

Shortly thereafter, General Electric implemented the Six Sigma methodology under the leadership of Jack Welch in 1990s. GE extended Six Sigma by connecting it to results, as well as to executive compensation. GE also published financial benefits from Six Sigma in their annual reports. Six Sigma quickly became a widely adopted corporate practice and was implemented internally by many fortune 500 companies as an effective way of improving business performance.

Most Six Sigma programs also cover the aspects, tools and topics of Lean or Lean Manufacturing. Six Sigma and Lean are quite complimentary and work hand in hand drawing from each other’s strengths and together offering unmatched benefits to those who follow these disciplined approaches. Six Sigma is heavier on the analytics and focuses on minimizing process variability, shifting the process average and delivering within customer specification limits.

Lean takes a fundamentally sound and practical approach to focusing on eliminating waste and increasing efficiency. Lean, and its own popularity relative to the history of six sigma, began to crest and gain significant traction in the mid 1960's with the Toyota initiative "TPS” or Toyota Production System. The concepts and methodology of Lean however, were fundamentally applied much earlier by both Ford and Boeing in the early 1900s.

Because both Six Sigma and the revitalization of Lean have been only as recent as the last 30-50 years, Lean Six Sigma and its history continues to be written with every new deployment and company or organization striving to improve their business performance.

I see people listing themselves as “Lean” Six Sigma Master Black Belts from GE on LinkedIn with start dates of 1998 thru 2000. When did GE start credentialing staff as “Lean” Six Sigma Master Black Belts? People I have mentored who used to work for GE said there wasn’t a “Lean” program at that time at GE. Is that true?

Hi Rico,

Following Motorola, Welch implemented it in the mid-’90s, and by the late ’90s, and early 2000, many other Fortune 500 companies followed suit. Keep in mind that there were many business units within a company the size of General Electric. Some may not have been part of the first few waves of implementation until they had an efficient and replicable program.

It sounds to me like it is possible that you review candidates for potential employment in your professional capacity. If this is the case, I would not be too concerned about the provider’s credibility as much as the recency and demonstrated “practice” of the candidate, with an emphasis on their related activities and successes.

In the mid-1900s, Boeing, Ford, and Toyota began experimenting with Lean manufacturing, a process aimed at reducing […]