Importance of the Six Sigma Primary Metric

Six Sigma Primary Metric

Primary Metric:

The Six Sigma Primary Metric is mandatory! How does one know if a project does what it sets out to do? Every project must choose the right metrics to determine success. Primary metrics are the center point for the work to ensure that the direction and decisions made throughout the project are based on data. This metric is what stakeholders will use to judge the project's success.

The Six Sigma primary metric is a generic term for a Six Sigma project's most important measure of success. Choosing the primary metric should not be taken lightly. A Six Sigma expert should play a significant role in determining the primary metric to ensure it meets the characteristics of a good one. The Black Belt, Master Black Belt, or Champion defines the primary metric. A primary metric is an absolute must for any project and should not be taken lightly. Here are a few characteristics of good primary metrics.

Primary metrics should be:

- Tied to the problem statement to ensure that what is being measured is a direct indication of whether the problem is being solved or not.

- Measurable.

- Expressed with an equation, so that the Y, can be expressed as a function of the x’s.

- Aligned with business objectives, the primary metric should be correlated to business results.

- Tracked at the proper frequency (hourly, daily, weekly, monthly, etc.); in other words, they should be something that can be tracked frequently enough so that action can be taken quickly when the metric changes.

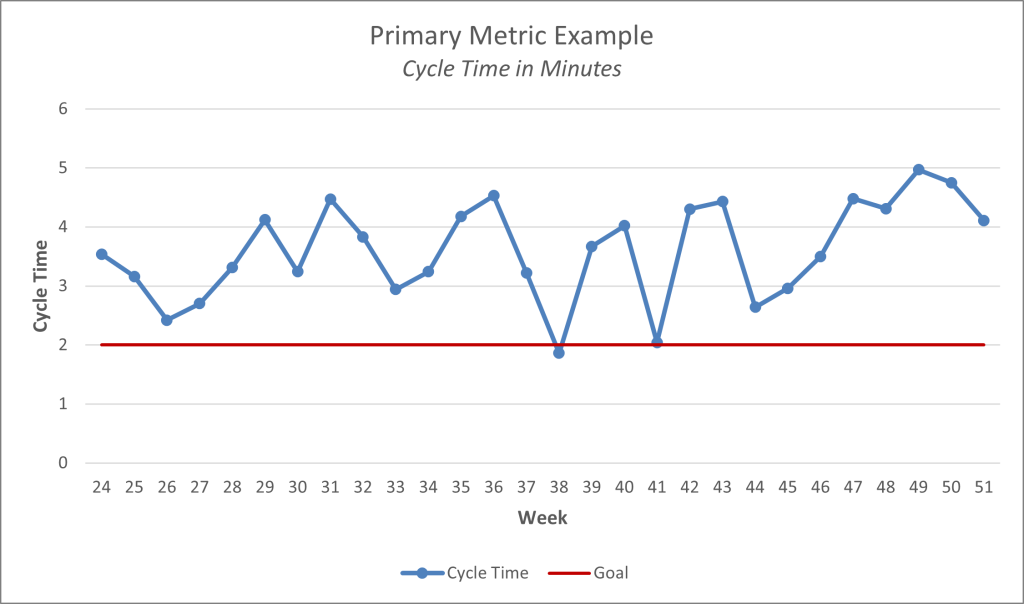

- Expressed pictorially over time with a run chart, time series, or control chart

- Validated with an MSA

The Primary Metric in Six Sigma is the reason for your work, the success indicator, and the beacon. The primary metric is of utmost importance and should be improved, but not at the expense of your secondary metric. Do not trade one problem for another. Solutions need to be balanced. Ensure you do not create an issue elsewhere when implementing a solution to improve your primary metric. That is why secondary metrics are important.

Secondary Metric:

The secondary metric is the thing you do not want to be sacrificed for a primary improvement. A secondary metric ensures problems are not just “changing forms” or “moving around.” The secondary metric keeps us honest and ensures we are not sacrificing too much for our primary metric. If your primary metric is a cost or speed metric, then your secondary metric should probably be some quality measure. For example, if you were accountable for saving energy in an office building and your primary metric was energy consumption, then you could shut off all the lights and the HVAC system and save tons of energy . . . except that your secondary metrics are probably comfort and functionality of the work environment, so that will not bode well.

The Six Sigma primary metric is often missing or poorly represented, which spells doom for most Six Sigma projects. Certification candidates try to skip past putting together a true measure of the problem, the measure for success.

It is paramount that Six Sigma candidates take the time to gather historical data about the problem they are trying to solve, and it should be clearly depicted in some form of a time series chart, control chart, or run chart. Without a primary metric tracked at the proper frequency, it will be difficult, if not impossible, to demonstrate process improvement, much less stability.

The Six Sigma Primary Metric is Critical to Success!

Learn more about Six Sigma and how mastering process improvement methods can put your career on a new trajectory.

Hi

I’m working in big dairy company .

I like to know more about primary metric.

for example: what is “unit” in our production line >? is it process order or inspection lot or one final product?

Can you help me?