Lean Six Sigma Problem Solving and the D.M.A.I.C Methodology

Together, the Lean Six Sigma Problem Solving and the DMAIC Methodology have successfully existed over the last 50 years. It is a proven approach that combines the principles of Lean and Six Sigma to optimize processes, reduce defects, and achieve operational excellence. And, it is critical to note, that the methodology of DMAIC (Define, Measure, Analyze, Improve, Control), which is the core of Lean Six Sigma, is why Lean Six Sigma remains highly valued today. Let's explore how DMAIC enables you to solve problems efficiently, enhance productivity, and deliver exceptional results. Join me on this brief journey as I outline how D.M.A.I.C. is the core of Lean Six Sigma Problem Solving.

Understanding Lean Six Sigma Problem Solving and DMAIC

Lean Six Sigma is a methodology designed to improve operational efficiency, reduce waste, and enhance overall quality. It embraces a fact-based, data-driven approach and provides organizations with a structured framework to identify and address issues effectively. That framework is the DMAIC methodology. It's a well-defined project management approach to discovering the Y=f(x) equation, where the "Y" is the measure of that thing you're trying to improve, and the "x's" are "influencing" (good or bad) that "Y's" output.

Define Phase

The first step in every Lean Six Sigma Problem Solving effort is to define the problem and the goal. It's no different than looking at a map before a road trip with your friends. You can map your route if you know..

-

- Where you are

- Where you're going.

If you don't know either of those, you'll be driving around aimlessly. Of course, there are several other important elements to the define phase and certainly the entire DMAIC process. However, without a quantifiably defined problem and goal.. your efforts will be fruitless.

Measure Phase

Once the problem is defined and the goal is set, you have the "Y" part of the "Y"=f(x) equation. It's time to put several things in motion.

-

- Begin measuring your "Y" over time and as frequently as necessary.

- Brainstorm all the potential "x's" influencing the "Y"

- Prioritize the potential "x's"

- Begin measuring the "x's" in such a way that you can correlate them to your "Y"

Analyze Phase

If you're following this process in your project, then it's time to start using all the data you've been collecting. The intent of the Analyze phase is to "determine the root cause", but, to do so with data! Not conjecture. In Analyze, you should be focused on facts, data, and input from subject matter experts. Your focus will be:

-

- Eliminate insignificant "x's"

- Validate significant "x's"

If it sounds easy.. it's not. It's always complicated, and oftentimes, you'll discover that there are inputs to the "x's" that require measurement and analysis. It's not a linear process, it's iterative. But if the steps are followed and repeated as necessary.. you'll get there.

Improve Phase

The expectation in a DMAIC or "Lean Six Sigma Problem Solving" project is that when you think you've determined the root cause(s) that most significantly influence your "Y," you then need to prove it, and/or implement it. So now, with a clear understanding of the problem and its root causes, the Improve phase focuses on generating and evaluating potential solutions. Engaging cross-functional teams to collaborate and brainstorm ideas, pilot-test proposed improvements, and implement changes. Continuous data monitoring, process and SME feedback, and iteration ensure solutions will align with the desired result of your "Y" output. Improve is where as a Lean Six Sigma practitioner you'll be called upon to demonstrate advanced facilitation, communication, and project management skills.

Control Phase

Once solutions are implemented, the control phase ensures the improvements are sustained over time. You'll develop control plans to monitor and measure process performance, establish standard operating procedures, and provide ongoing training. By maintaining control, you can prevent regression and ensure continuous improvement in the long run. Control involves monitoring critical "x's" over time and managing them to yield expected results from your "Y." It requires people to be accountable, action plans and re-action plans to be in place, mitigation plans, communication & notification plans, training plans, etc. The control phase is as critical as the others but is often overlooked. Be sure to put sustainable plans in place to maintain your improvements.

Using Lean Six Sigma Problem Solving and DMAIC

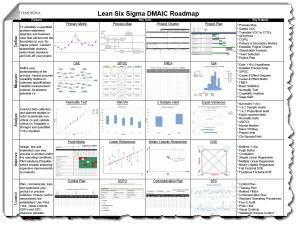

While the structure of the D.M.A.I.C. methodology is simple and logical, the sheer volume of information, tools, techniques, templates, and data analysis that it contains suggests it's not simple. Yet, each tool or technique is fairly simple and amazingly effective when used timely and appropriately. It's the Lean Six Sigma Black Belt's job to know as much and as many tools, and techniques as possible so that he or she is prepared to face the problems, issues, roadblocks, and opportunities that reveal themselves throughout a Lean Six Sigma project. This is why a Lean Six Sigma Black Belt commands a six-figure salary. The knowledge and skills acquired through a Lean Six Sigma Black Belt Certification can be a major career booster.

Lean Six Sigma Problem Solving and the D.M.A.I.C. methodology provide organizations with a systematic and data-driven approach to address challenges, enhance productivity, and achieve operational excellence. By learning and embracing DMAIC and all the tools and techniques it embodies, organizations will look to you for leadership, expertise, and results. And you, in turn, can push forth continually learning and advancing your career.